Toyo Tires Proprietary Technology for Improved Wear Resistance

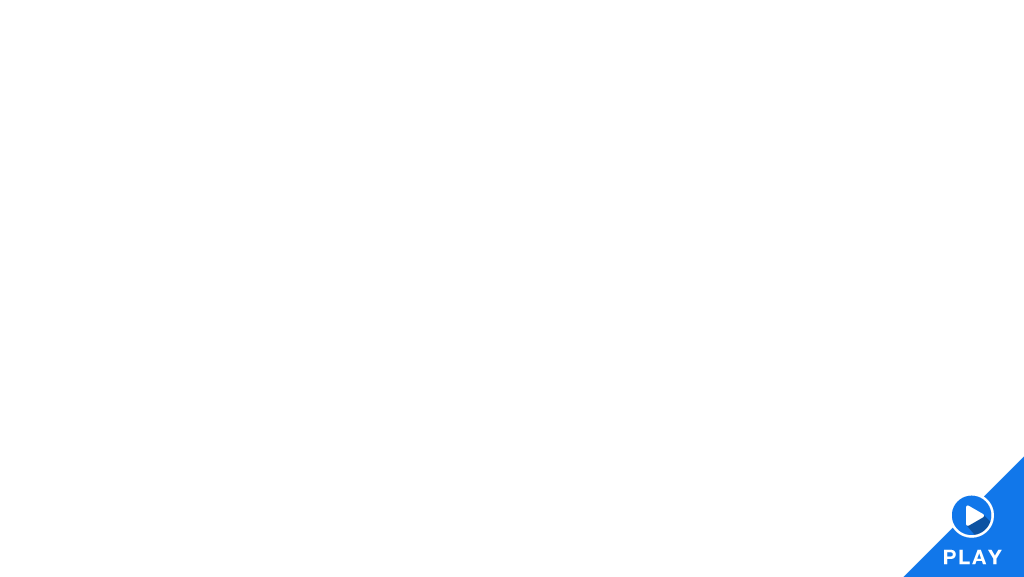

1. Further Required Tire Performance

The era of evolution in tire performance (such as wear resistance, wet performance, and rolling resistance performance) has arrived.

Among these requirements, Elongated High Strength Rubber Design focuses on wear resistance performance.

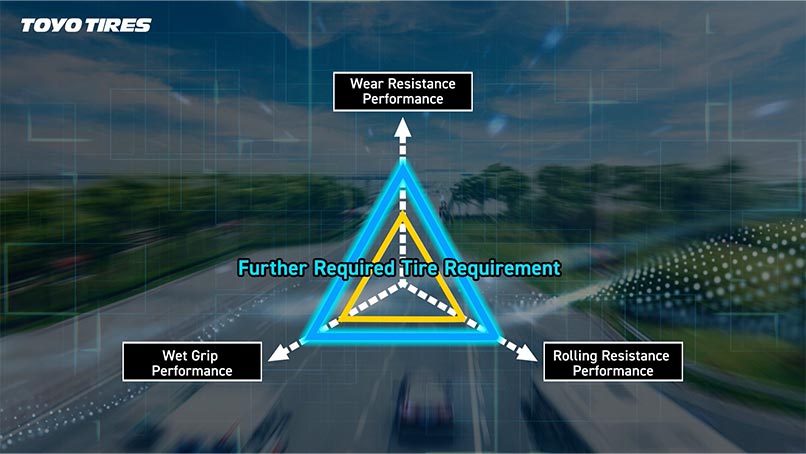

2. Main Cause of Tire Wear

Main cause of tire wear: the uneven road surface scratches the surface of the rubber and the rubber becomes detached.

Wear resistance enhancement has been necessary to improve rubber strength (in cases of rupture).

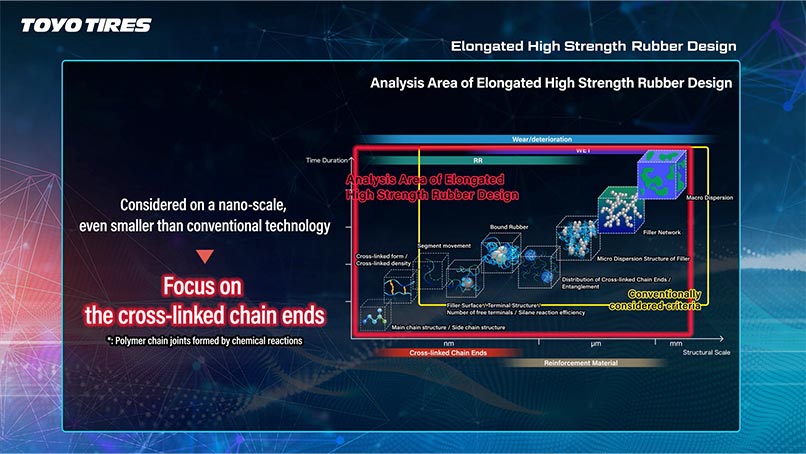

3. Analysis Area for Elongated High Strength Rubber Design

By focusing on the cross-linked chain ends, the area of study is expanded.

In the previous technology, the study area was wear, WET, RR, and reinforcement, while the Elongated High Strength Rubber Design examines at a smaller nanoscale.

Focusing on the "cross-linked chain ends," which is the joint of the polymer chain formed by the chemical reaction, we expanded the study area to the form and density of the cross-linked chain ends, the main chain structure, and the side chain structure.

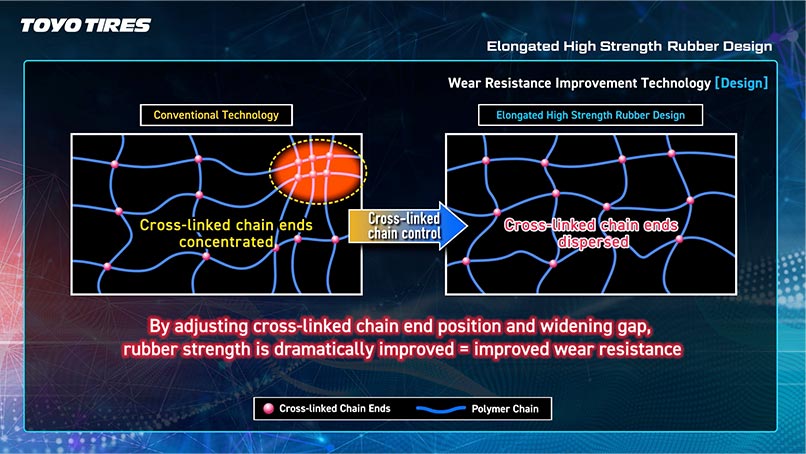

4. Wear Resistance Improvement Technology [Design]

By adjusting the position of the cross-linked chain ends, the rubber strength is dramatically improved. (=Improved wear resistance)

In the conventional technology, the cross-linked chain ends concentrate locally, and the polymer breaks in the area where the stress concentrates.

In the new technology, by controlling the cross-linked chains by dispersing the cross-linked chain ends and widening their gaps, rubber is designed to be resistant to break. This has dramatically improved rubber strength and improved tire’s wear resistance.

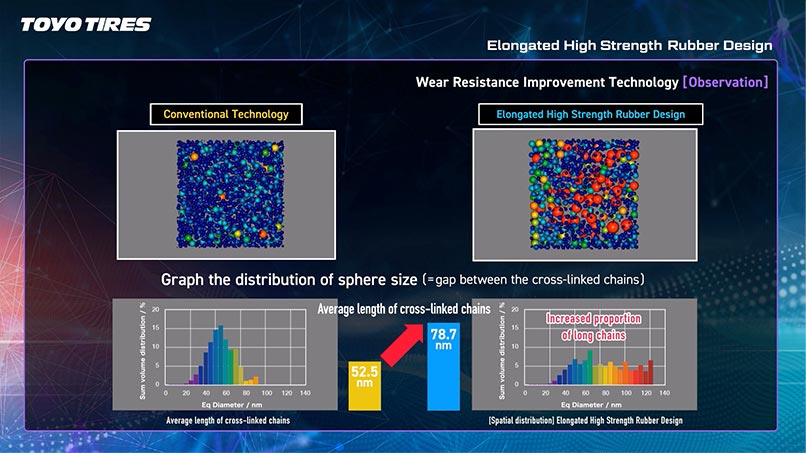

5. Wear Resistance Improvement Technology [Observation]

The newly designed rubber has been observed at nanoscale using Transmission Electron Microscope (TEM).

The newly designed rubber was visualized in 3D TEM and extracted by image processing.

Then, gaps between cross-linked chain ends were extracted and divided using image processing.

The analysis was carried out by fitting proximity spheres to the divided blocks.

In the rubber designed by Elongated High Strength Rubber Design, the proportion of long chains (in the spatial distribution between cross-linked chains) increased.

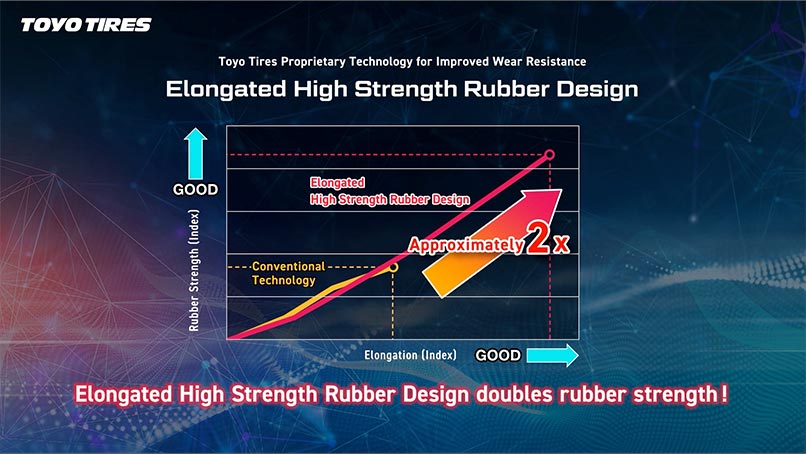

6. Realization of High Elongation and High Strength of Rubber

Elongated High Strength Rubber Design improves rubber strength by approximately 2 times as much as conventional technology.

7. Longer Wear Life, Higher Fuel Efficiency

Rubber strength enhancement has improved tire wear life.

In addition, by reducing the amount of rubber used, it has become possible to reduce tire weight and improve fuel efficiency (=reduce rolling resistance).

It is possible to save resources, improve fuel consumption efficiency, and reduce CO2 emissions through use of high-growth and high-strength rubber.