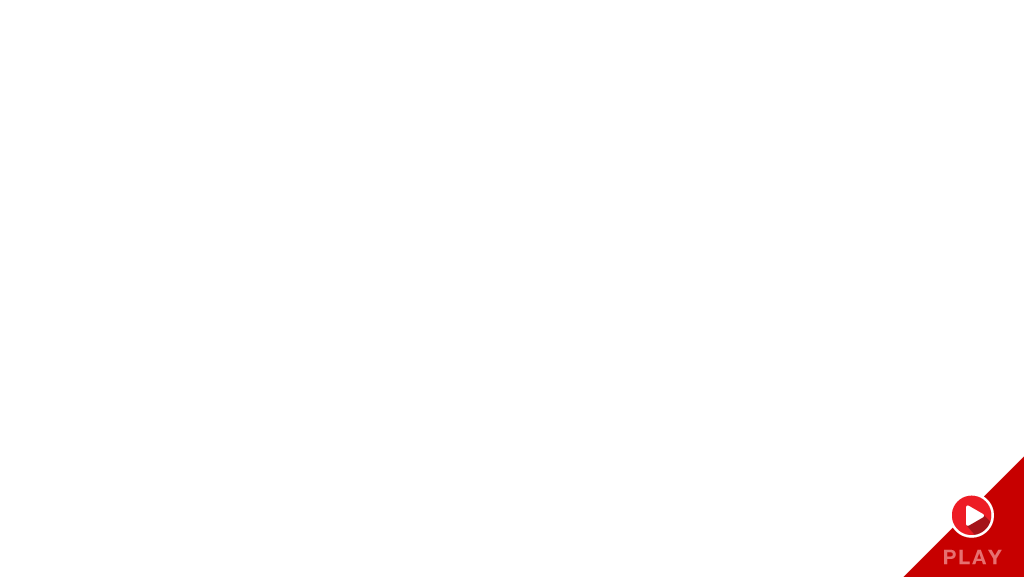

Fundamental Material Design Technology

1. What is Nano Balance Technology

As the raw material for tires, rubber compounds are comprised of various components such as carbon black and silica.

The molecular structures and the properties of the compounds have an intricate relationship and create the performance of the tire.

We have developed ideal rubber materials with high precision through “simulation,” “function creation,” “precision control,” and “research” of the materials that make up these tires at the nano level (1 nanometer = 1 billionth of a meter). That is Nano Balance Technology of Toyo Tires.

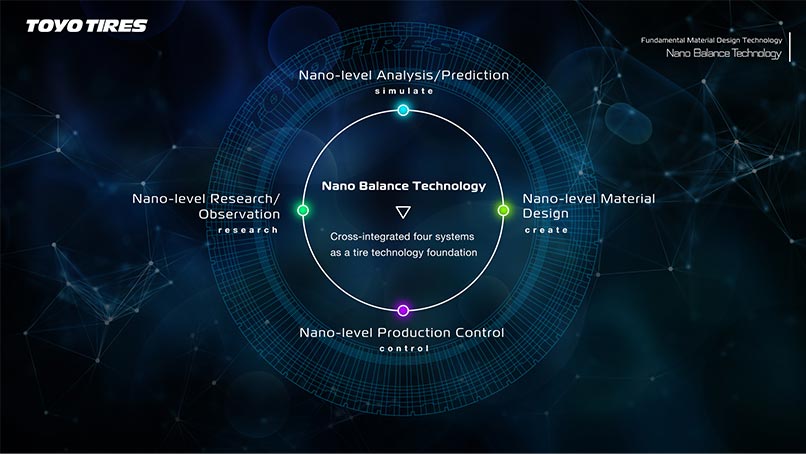

2. Nano-level Analysis/Prediction [simulation]

Analyze the compounding ratio of filler*1 and polymer*2 at the nanoscopic level to obtain the required performance

Toyo Tires has developed graphing technology, “Nano-level tan delta (tanδ) simulation,” to find the master curve of energy loss (viscoelasticity) through the microscopic structure of rubber.

Based on this industry-first technology, by looking at the “low-frequency region” (indicating fuel efficiency performance) and the “high-frequency region” (indicating wet grip performance), it has become possible to graph and quantitatively evaluate the characteristics of rubber material.

*1 [Filler] General term for substances such as carbon black and silica that are added to raw material rubber to improve reinforcement, processability, and cost reduction

*2 [Polymer] Molecular components that make up natural or synthetic rubber

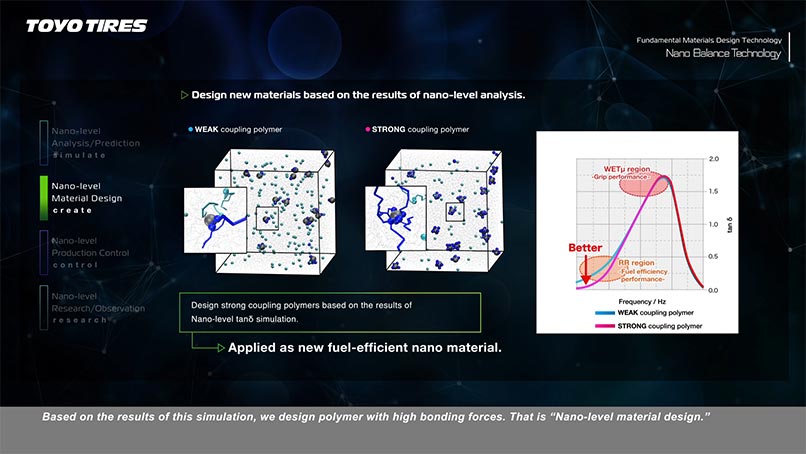

3. Nano-level Material Design [Function Creation]

Design new materials based on the results of nano-level analysis

We have designed strong coupling polymers based on the result of the “Nano-level tan delta (tanδ) simulation.”

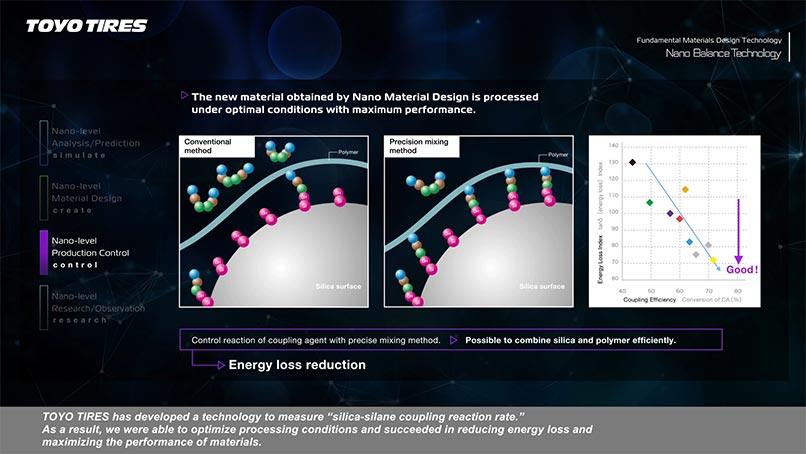

4. Nano-level Production Control [Precision Control]

Maximize performance by processing the new materials gained through nano-level material design under optimal conditions

Even if super quality raw materials are used, best performance can not be obtained without the processing technology to maximize performance. In nano-level processing, silica compounds are precisely mixed with the temperature controlled so that the coupling agent's reaction to silica can be precisely controlled. Because of this, it has become possible to efficiently combine polymer and silica.

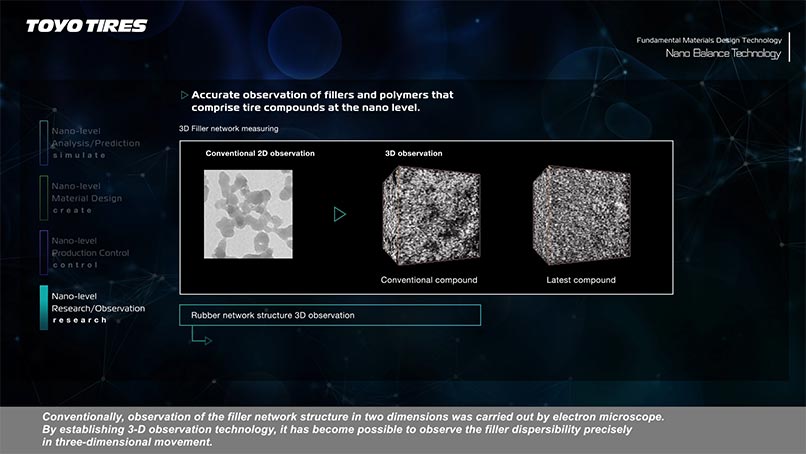

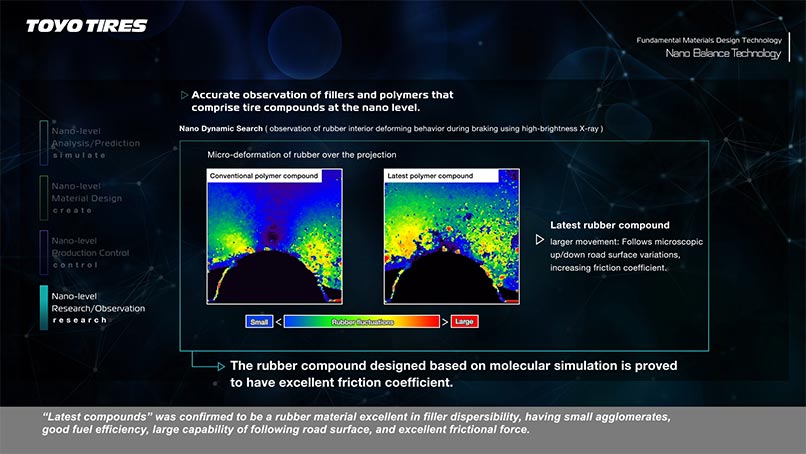

5. Nano-level Research/Observation [Research] -1

Precisely observe at the nano-level the state of the filler and polymer that make up the tire compound

We developed 3D observation technology to observe more precisely the network structure within the tire compound in three-dimensional movement. With the latest rubber compounds made using Nano Balance Technology, we have confirmed that uniform dispersion control is possible.

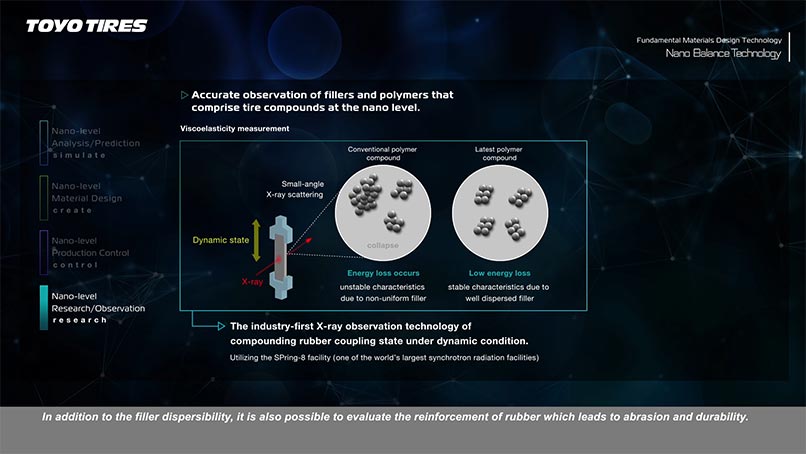

5. Nano-level Research/Observation [Research] -2

At SPring-8, one of the world's largest synchrotron radiation facilities, we established X-ray observation technology to acquire information of filler structure under dynamic conditions, the first of its kind in the industry. In addition to filler dispersibility, it is now possible to evaluate the reinforcement of the rubber, which leads to abrasion resistance and durability.

5. Nano-level Research/Observation [Research] -3

Due to advances in nano-level research, we have established “Nano Dynamic Search,” which conducts a three-dimensional observation of rubber materials and a research of the internal structure of rubber in dynamic conditions. We observed the deformation in the rubber during braking with high intensity X-ray. This also confirmed that the rubber compound, which was designed based on molecular simulation, has an excellent coefficient of friction.