Advanced Tire Operation Module

Innovative tire manufacturing technology developed independently by Toyo Tires.

1. What is A.T.O.M.

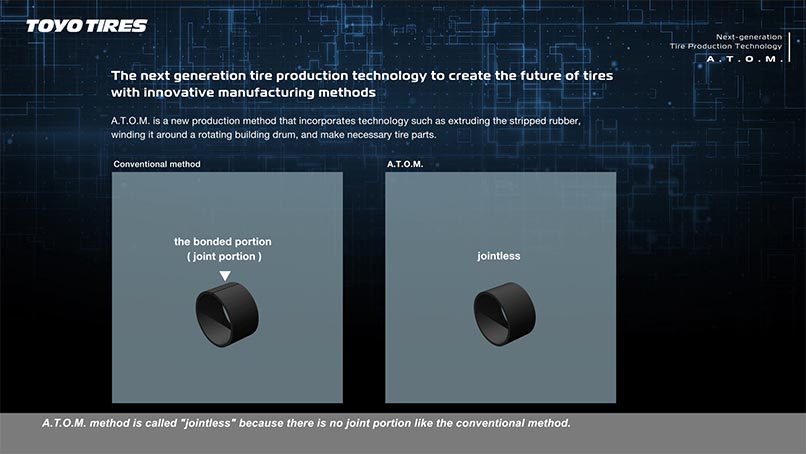

It is a new production method to manufacture required parts and materials for tires, by winding and gluing a thin ribbon-shaped strip of rubber, approximately 15 mm wide, that is extruded onto a rotating building drum.

In the conventional production method, tire parts such as wide section of treads are wound around building drum and both edges are aligned and laminated together to make a green tire.

The section where the edges are laminated together is called a “joint.” In contrast, the A.T.O.M. production method does not create joints as found in the conventional production method, and is referred to as “jointless.”

2. Improvement in Tire Uniformity

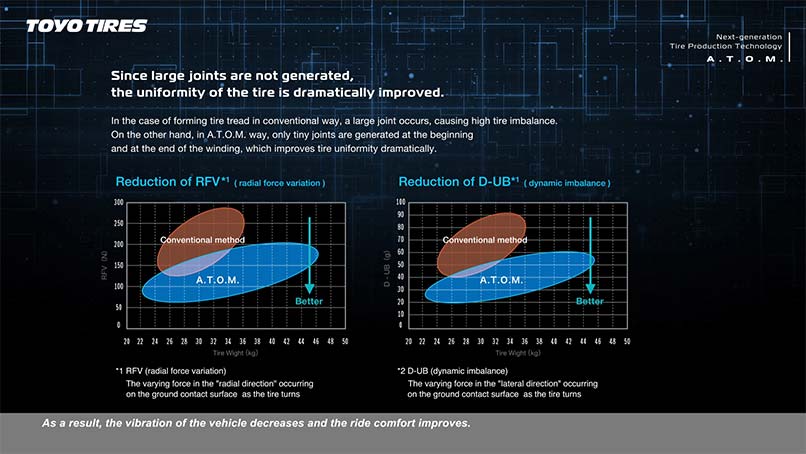

Since large joint portions do not occur, tire uniformity has been dramatically improved.

When the tread is formed using a conventional thick and flat rubber sheeting, a large joint occurs, with the potential to cause tire imbalance. In A.T.O.M., because the tire is formed by winding a long and thin strip of rubber, there is only a small break at the beginning and the end, which drastically reduces the impact on the balance of the tire.

3. Compact Facility Area

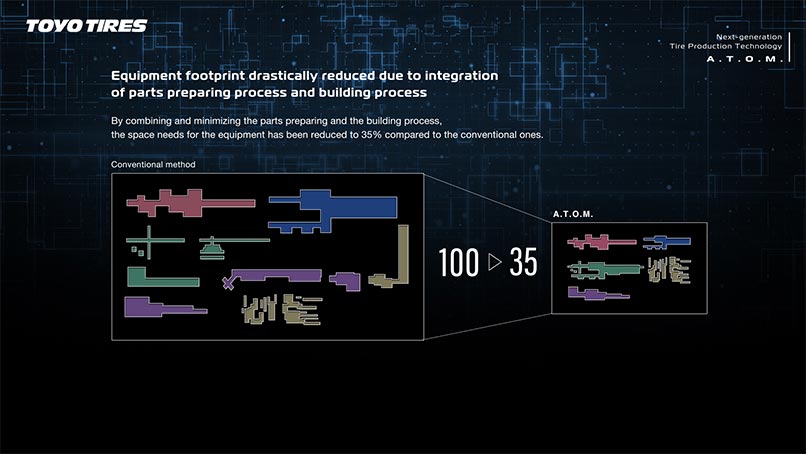

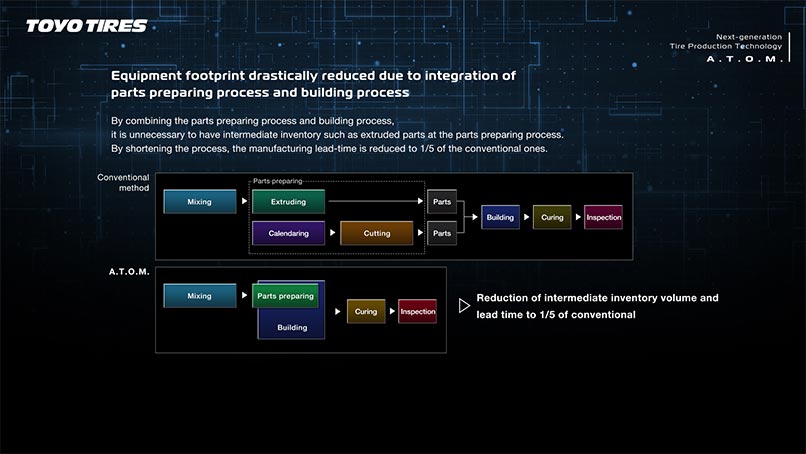

Combining the parts preparing process with the building process, and making it more compact, we have made it possible to reduce the space required for the equipment by approximately 35%, compared to the conventional production method.

4. Drastic Reduction in Lead Time

Combining parts preparing process with the building process has made it unnecessary to store intermediate inventory such as extruded parts that are produced during the parts preparing process.

As a result, the lead time is now reduced to 1/5th of the conventional production method.

5. Realization of Multi-Product, Small-Lot Production

Due to automated changeover and management using computers, multi-product, small-lot production has been implemented.

Under the conventional production method, tire parts must be switched out for each product type, and time is lost during the switching phase of product types. In contrast, it is possible to manufacture different parts using A.T.O.M. through a change in program, which is managed by computer, enabling efficient multi-product, small-lot production.

6. Potential for Overseas Expansion

Making manufacturing facilities more compact and computer-managed production in small-lot sizes have drastically reduced time and costs

This has made it easier to set up factories overseas.

In 2017, 45% of the tires produced for passenger cars at Toyo Tires was manufactured under A.T.O.M..