Press Release

Apr. 22, 2020

Advancing the Processing Technology for Rubber Materials Using Materials Informatics Technology

Hyogo, Japan - April 21, 2020 - Toyo Tire Corporation (Headquarters: Itami City, Hyogo Prefecture; President & CEO: Takashi Shimizu, hereinafter, “Toyo Tire”) aims to develop and provide high-performance tires that can meet the requirements of society through advancing technological innovations of its exclusive “Nano Balance Technology,” our proprietary rubber material development platform. As part of the Nano Balance Technology suite, we are pleased to announce for the first tire that we have developed technologies that use materials informatics (hereinafter, “MI”)*1 to predict the properties and optimize the material structure of rubber materials.

*1)This technology uses artificial intelligence (AI) and other technologies to enable the discovery of new and alternative materials with greater efficiency than conventional methods.

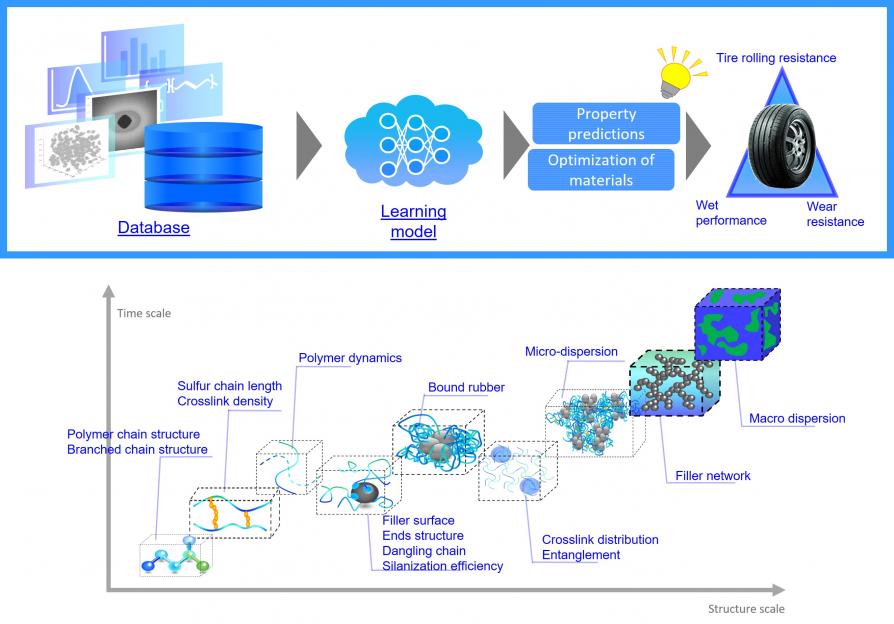

(An example of predictive modeling applied to the material structure of rubber)

In recent years, AI (machine learning) and other technologies have been used in the material development process, but MI technology is about to change the field of material development. Material development has typically been a very time-consuming trial and error process relying on the experience of engineers and repeated experimentation.

Since 2018, Toyo Tire has been using MI technology based on our accumulated data assets to validate the predictive technology of recipes and physical properties. Through advancements of the precision of the technology, we also validated the expanded application of the target data, such as linking it to external information in 2019. Going forward, we will develop an environment where our in-house data can be put to full and effective use. We will also use novel analysis methods and predictive data to realize new materials that use MI technology, which highly optimizes development, to develop high-performance products while at the same time reducing the time and cost of development.

■ Recipe Development Using Data Resources

Rubber is a composite formed by adding filler and other ingredients to the base material polymer. Each ingredient directly affects the characteristics of the product, thus requiring advanced control in terms of the type and amount, as well as adjustments in the processing method. The introduction of MI technology allows us to build a system that creates highly accurate predictions of properties and recipes, which enables efficient material development with minimal testing. The system implements a nonlinear regression model*2, which can make expanded predictions that go beyond existing knowledge, by importing external information to a database. This system will also be used in the development of high-performance materials.

*2)This refers to data modeled by a function based on the nonlinear relationship between the variables used for predictions.

■ Using Digital Technology to Develop New Materials

In the field of Nano Balance Technology, Toyo Tire utilizes various tools to evaluate the elements of material properties by each hierarchical structure, and to extract development issues.

Data for material and chemical structures that is obtained by analysis is entirely different from material property data. Therefore, the data for material and chemical structures has mainly been used as information for indirectly predicting material properties. Adopting the newly developed MI technology to material analysis has made it possible to calculate prediction values of material properties from structural information. As the technology lends itself to the inverse problem of optimizing the structure according to targeted property values, we intend to apply and expand it to the field of new material development.

These technologies were realized in collaboration with SAS Institute Japan Co., Ltd. (President: Tetsuya Hotta)*3.

*3)SAS Institute Japan is a leading company in analytics (https://www.sas.com/ja_jp/home.html) that promotes the utilization of AI technology and the introduction of advanced IoT solutions for a wide range of industries through innovative software and services.

Toyo Tire develops high-performance and high-quality products by leveraging both of its own rubber material development Nano Balance Technology, and its tire design base technology, T-MODE. We also intend to explore the potential of using tires as a sensing device and create high value-added products that contribute to tomorrow’s mobile society.

Going forward, Toyo Tire seeks to fully harness MI technology in the rubber development process and enhance the value of products that we develop.

□Nano Balance Technology

Nano Balance Technology is a technology for developing ideal rubber materials with high precision through observation, prediction, material design, and production control, at the molecular (nano) level.

We use this to achieve a high level of both performance extremes, tire rolling resistance (low fuel consumption performance), and braking performance (wet grip performance), to offer a range of high value-added products. Moreover, even for trucks and bus tires, we have launched a series of products made by using low fuel consumption tread that have excellent heat generation, based on the material design technology of Nano Balance Technology.

For reference

As mentioned earlier, Toyo Tire is advancing the development of automotive tires based on a combination of our rubber materials base technology and tire design base technology. Our technological innovations using AI in the fields of simulation technology and new sensing technology have been ongoing even before we adopted MI technology for rubber materials. Here are some examples.

□Real-time simulations using the newly advanced “T-MODE”

(Released on July 18, 2019: https://www.toyotires-global.com/press/2019/190718_e.html)

Toyo Tire advanced and systemized the automotive tire development process, calling it T-MODE, which it originally established as a development platform for automotive tires 20 years ago.

Toyo Tire succeeded in integrating data collected from simulations run in T-MODE by utilizing SPDM*4. In February this year we established a revolutionary real-time simulation technology that by using AI can immediately predict tire performance.

A hierarchical diagram was prepared which transects tire design specifications and tire performance. By applying this with data science methodologies, we succeeded in visualizing the relationship between tire design specifications and tire performance. Based on this relationship, we conducted machine learning using this simulation data and found it possible to make calculations in a short time and produce precision predictions.

*4)SPDM: Abbreviation for Simulation Process and Data Management. An infrastructure system which can unify all forms of data and share standardized processes.

□Using “T-MODE for snow prediction technology

(Released on February 25, 2020: https://www.toyotires-global.com/press/2020/20200225_e.html)

Previously, Toyo Tire established a method for predicting the snow traction performance of a tire in specific types of snow quality (fresh snow and slush). However, by using the newly evolved simulation base technology of T-MODE, it is now possible to predict with a high level of precision the snow traction performance of a tire in the actual environment in which it is being used.

This allowed Toyo Tire to successfully visualize the block and sipe deformation during braking in various environments in which tires are used. As a result, we can now properly consider the tread pattern best suited for the intended environment.

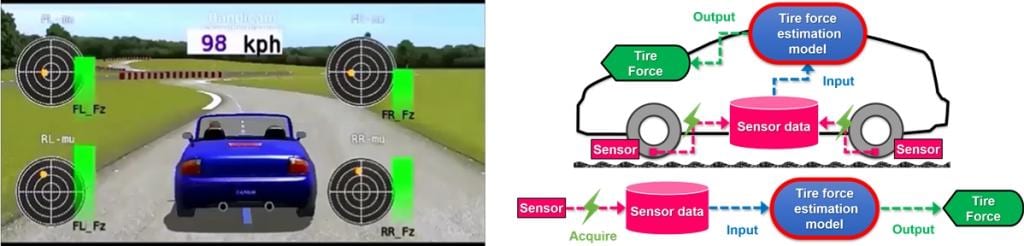

□Toyo Tire’s Tire Sensing Technology Concept

(Released on February 25, 2020: https://www.toyotires-global.com/press/2020/200214_e.html)

Toyo Tire is developing tire sensing technology that visualizes tire performance while driving in real time by using the tire as a sensor in conjunction with AI and digital technologies to detect information about the tire and road conditions while driving. The tires on the car that we drive are invariably different, i.e. far from uniform, due to their history of use and performance conditions. As such, the information essential for each car will be different. As tires — the only part of a car that is in contact with the road surface — take on a new role in the new mobility society, Toyo Tire will strive to create new values through open innovation.

(Conceptual image)

Toyo Tire Corporation

Corporate Communications Dept.

Hyogo Head office Telephone: +81-72-789-9100 Facsimile: +81-72-773-3272

Press Release is intended for media purposes, and is current of the date of publication.

Information is subject to change with or without notice.