Challenges

- Environmental contribution (CO2 emissions reduction): Reducing tire rolling resistance, improving EV compatibility, saving resources

- Safety: Maintenance-free products, diagnosis of tire wear

- Commercializing airless tires

- Ultimate enjoyment of driving and sophisticated features

Relevant stakeholders

Direct:Customers(consumers), suppliers, employees, research institutions

Indirect:Shareholders and investors, creditors, local communities, NGOs/NPOs, industry groups

Our policy

We know that the sustainable future for tire and automotive parts manufacturers will only be ensured once a society of sustainable mobility has been created. That’s why we are working to help establish a society of sustainable mobility that reduces environmental impact, prevents traffic accidents, and facilitates efficient transportation and mobility. In addition to providing the necessary elements for promoting sustainability, we believe that using our unique products and services to satisfy the various features that people expect from superior mobility life will create added value designed to support a diverse mobile society, so that is what we intend to do.

Responsible executive (as of April 2025)

Director, Corporate Officer and Vice President of R&D Headquarters

Organizational responsibilities

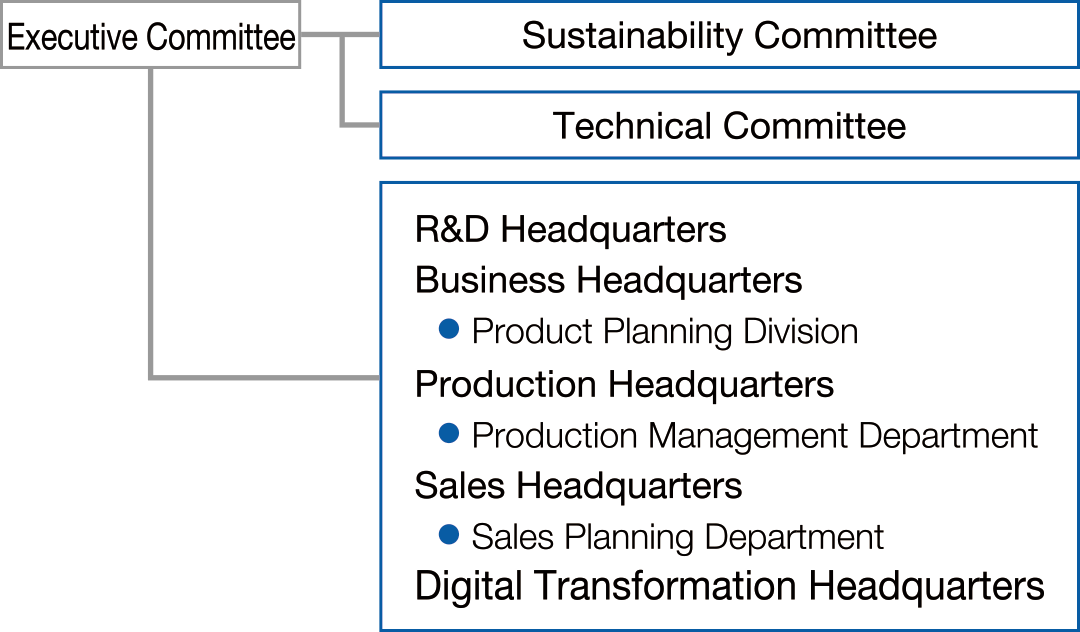

Spearheaded by our R&D Headquarters, we are working together with product planning, production management, sales planning and digital transformation (DX) functions and promoting sustainability-related activities based on various themes that correlate with the aims of our medium-term business plan.

The Technical Committee oversees the overall implementation of those activities and reports progress to the Sustainability Committee.

Reporting systems

- Reporting hotline (whistle-blowing system): For executives, employees and suppliers

- Customer Relations Department: For customers (consumers) and local communities

- Online inquiry form: For customers (consumers), shareholders and investors, and NGOs/NPOs,

In addition to the above routes, our technical service departments, Group sales companies and distributors also receive inquiries and complaints.

Main resources for promoting activities (2024)

- R&D expenses: 13,587 million yen *including 1,716 million yen for basic research expenses

- Expenses related to environmental conservation during R&D activities: 585 million yen

- Capital investment in rationalization, improving quality and enhancing production facilities: 17,673 million yen

- R&D bases: 5 bases (Japan, US, Germany)

- We are strengthening our unique technologies and developing differentiated products by encouraging cooperation between our R&D functions in Japan, the US and Europe. We also conduct joint research with multiple universities and research institutes.

Reducing the environmental impact of mobility

Improvements in fuel efficiency with each new model release

Reducing vehicles’ CO2 emissions is a challenging issue that needs to be addressed throughout the supply chain in order to achieve carbon neutrality by 2050. At Toyo Tire Corporation, our goal is to help reduce CO2 emissions per tire by 20% by 2030 compared to 2019 levels and our functional organizations collaborate to develop products. When planning model changes for priority, or core, products based on our medium-term product development plan, the product planning function works closely with the sales function to monitor trends in individual markets and also incorporates performance and functions that can also be applied to EVs, including fuel efficiency, into its product development requirements. In anticipation of potential trends in the automotive market and required levels of tire performance and functionality, our R&D function has established a technology development framework that collates repeated refinements of platform technologies over a medium- to long-term time span and achieves a high-level of product planning. We will continue to improve fuel efficiency across our product lineup to help reduce the environmental impact of mobility.

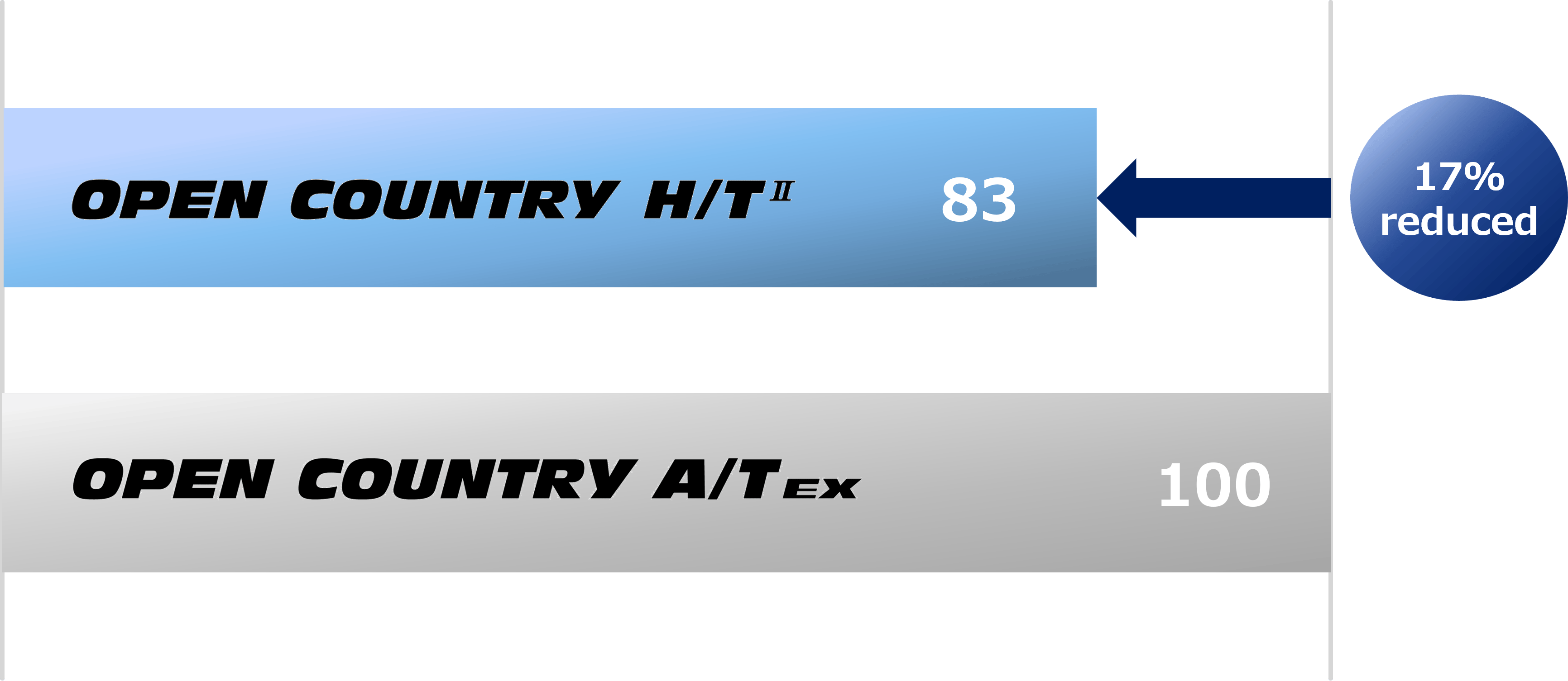

In April 2025, we launched the OPEN COUNTRY H/T II highway terrain tire*1 in the Japanese market that complements the OPEN COUNTRY series’ renowned designability with added quietness and fuel efficiency. After initially launching the OPEN COUNTRY series in Japan to coincide with the expansion of the SUV market, we received multiple requests from dealers and other channels to enhance the product lineup by offering an aggressive pattern design and performance that was more attuned to city driving. That feedback inspired the development of the OPEN COUNTRY H/T II. Nano Balance Technology was used to increase the amount of silica, thus improving rubber strength, and super active polymer was added to enhance silica dispersion, allowing us to optimize fuel efficiency, wet performance, and wear resistance to a high degree. Rolling resistance has been reduced by 17% compared to the conventional OPEN COUNTRY A/T EX, boosting fuel efficiency.

- *1 A category of quieter tires that are better suited to driving on paved roads and highways and offer higher degree of driving comfort than the all-terrain category.

Rolling resistance(INDEX)

[Test conditions]

・Location: Toyo Tire Corporation indoor drum-type rolling resistance testing equipment

・Tire size: OPEN COUNTRY A/T EX 225/65R17 102H, OPEN COUNTRY H/T II 225/65R17 102H

・Rim size: 17X6.5

・Tire pressure: 210 kPa

・Load: 6.67 kN

・Speed: 80 km/h

- *Detailed data from the above-illustrated test have been delivered to the Tire Fair Trade Council.

- *There is no guarantee that the exact same results would be generated even if the test was repeated under similar conditions.

Our unique EV strategy

The global shift toward EVs may be slowing down, but they still represent one of the most effective ways of reducing automobile CO2 emissions, so we expect the spread of EVs to continue as energy conditions and automobile usage in different countries and regions evolve.

For example, if we break down CO2 emissions in Japan by sector, the transport sector accounts for roughly 20%*2 of total emissions, and modal shifts and other efforts to promote decarbonization are being pursued in earnest across the transportation industry. The shift toward EVs for transportation vehicles is also progressing, and commercial vehicle manufacturers have begun enhancing their EV truck lineup. Furthermore, now that major shipping and transportation companies are required to switch to non-fossil energy, demand for EV trucks will likely increase further going forward.*3

To address these trends, Toyo Tire Corporation introduced the NANOENERGY M151 EV ribbed tire specifically for light EV trucks into the Japanese market in June 2024, followed by the NANOENERGY M951 EV, the first studless tire for light EV trucks in September of the same year.

Considerable emphasis is being placed on EV cruising range on a single charge, and tires are expected to achieve a level of fuel efficiency (energy efficiency for EV tires) that helps extend that cruising range. Furthermore, we have to develop specific tire performance elements exclusively for EVs. This is because EVs exert a heavier load on tires due to their heavier weight when equipped with batteries and the increased acceleration performance generated by powerful EV driving force. The use of regenerative braking*4 can also affect the manoeuvrability of EVs.

When developing the necessary products, we designed an optimal compound using nano composite polymer, a material developed through our proprietary Nano Balance Technology, which reduced rolling resistance and improved wear resistance. With the NANOENERGY M151 EV in particular, we optimized the tire’s aerodynamic characteristics*5 by using our proprietary aerodynamic simulation, which derives advance predictions of the level of air resistance that tires and vehicles will likely be subjected to during driving and incorporates those data into the product design. This is the first time this simulation has been used in truck and bus tire design.

These two NANOENERGY EV tires were recognized at the 2024 Good Design Awards sponsored by the Japanese Institute of Design Promotion. They were highly praised for addressing the shift toward EVs in the transportation industry from a design perspective and for generating high-level improvements in both performance and durability.

- *2 National Institute for Environmental Studies, Japan

National GHG Inventory Document of JAPAN (P2-4) - *3 Japan Trucking Association 2024 (P6)

- *4 A form of electric braking that uses shaft rotation power to convert kinetic energy into electrical energy that can be captured and reused, as opposed to, under normal conditions, using a motor to convert electric power into a driving rotational force

- *5 Special characteristics associated with air resistance and air flow exerted on an object that is moving or being propelled through air

Ensuring safety and security in mobility

Balancing safety and environmental performance

Demand for small deliveries and other logistics has been increasing in Japan as the e-commerce market grows, but, at the same time, the enactment of the Work Style Reform Act in April 2024 has capped overtime hours for truck drivers leading to greater hiring of less experienced drivers. We recognize this situation and the broader requirements for even higher safety performance of transport vehicles and tires.

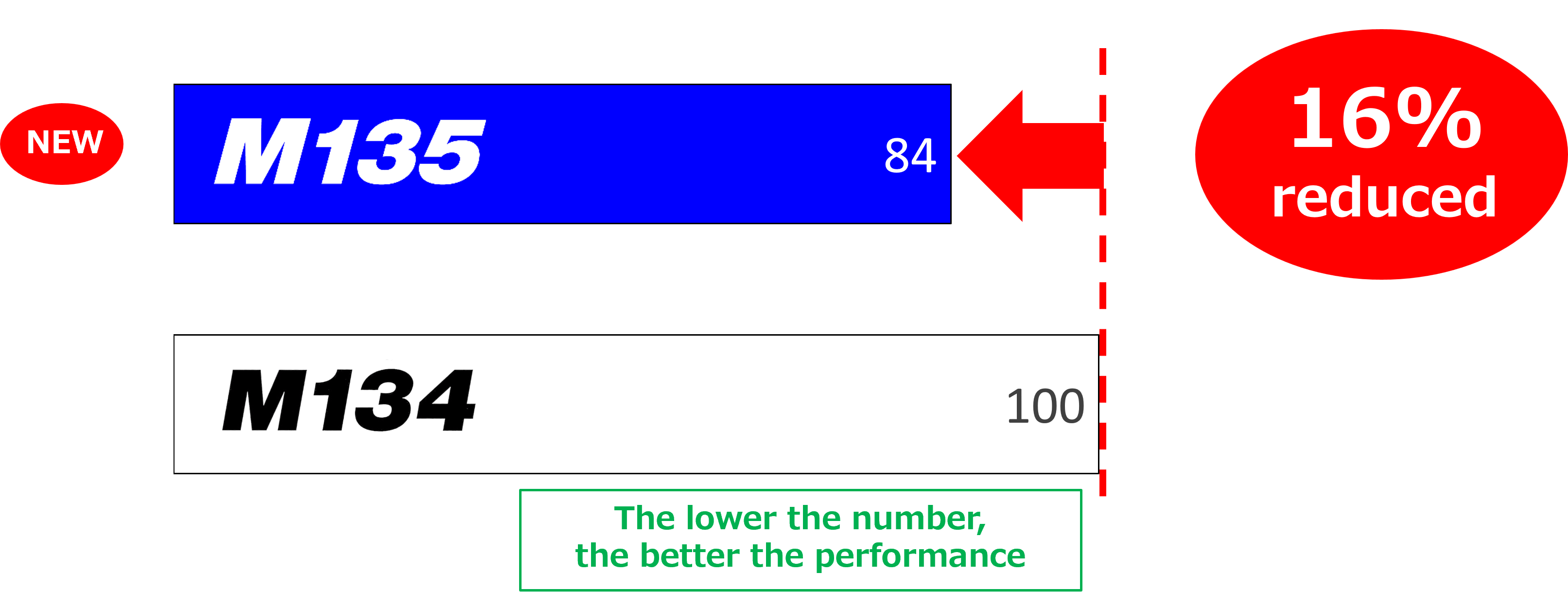

In June 2024, we launched the DELVEX M135 for the Japanese market, a ribbed tire for light trucks that offers both impressive wear resistance and fuel efficiency, while maintaining a high level of wet performance. The tire’s unique pattern design ensures strong tire grip over a wide range of truck loads, from fully loaded to near empty. Furthermore, the special wear-resistant LT compound developed using Nano Balance Technology has improved not only wear resistance and wet performance, which are considered to be the most important features for light trucks tasked primarily with small-lot deliveries, but also fuel efficiency. The estimated wear life on the DELVEX M135 has been improved by 32% compared to the conventional DELVEX M134, and rolling resistance reduced by 16%.

32% improvement in wear resistance compared to conventional products (estimated wear life in actual vehicle assessments)

[Test conditions]

・Evaluated size: 205/85R16 117/115N

・Location: General roads near the Toyo Tire Corporation tire test course

・Distance traveled: 12,000 km

・Vehicle used: 3-ton truck (Isuzu Elf TRG-NPR85AR), Engine capacity: 2.99 L, Axle arrangement: 2-D

・Rim size: 16X5 1/2J

・Tire pressure: 600 kPa

・With tire rotation

・Evaluation method: Comparison of total average estimated wear life of rear axle (calculated using a minimum remaining tread depth of 1.6 mm)

- *Detailed data from the above-illustrated test have been delivered to the Tire Fair Trade Council.

- *There is no guarantee that the exact same results would be generated even if the test was repeated under similar conditions.

16% reduction in rolling resistance compared to conventional products

(Measurement method)

Measure rolling resistance values on the Toyo Tire Corporation indoor drum-type rolling resistance testing equipment

[Test conditions]

・Evaluated size: 205/85R16 117/115N

・Location: Toyo Tire Corporation Tire Technical Center

・Testing equipment: Drum-type rolling resistance testing equipment

・Test method: UN R117 force-type

・Rim size: 16X5 1/2J

・Tire pressure: 600 kPa

・Load: 10.71 kN

・Speed: 80 km/h

- *There is no guarantee that the exact same results would be generated even if the test was repeated under similar conditions.

- *Detailed data from the above-illustrated test have been delivered to the Tire Fair Trade Council.

- *The rolling resistance test reduction rate does not match the actual fuel consumption reduction rate.

Adapting to changing weather patterns and road surfaces

The warmer winter weather observed in Japan, Europe, and other regions over recent years has changed winter road surface conditions. More surfaces are getting slippery due to large temperature differentials and the repeated freezing and thawing of snow, with snow melting during warmer daytime temperatures, turning into slush, and then freezing again at night when temperatures drop, turning to ice. The performance of studless tires needs to be improved to address these changing conditions.

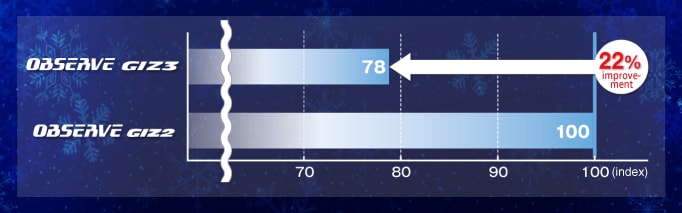

The Toyo Tire Group has especially been focusing on improving tire performance on ice because that has a significant impact on automobile driving safety. In August 2024, we launched the OBSERVE GIZ3 studless tire for the Japanese market with improved and longer-lasting braking performance and start-up traction on icy roads. Tire adhesion on icy road surfaces has been improved by using T-MODE snow prediction technology to design new tire patterns, along with rubber compounds that stay soft even in low temperatures thanks to a blend of new materials such as sustainable high adhesion gel and sustainer grip polymer. This has helped achieve a 22% improvement in braking performance on icy roads over the previous model, the OBSERVE GIZ2.

22% improvement in braking performance on ice compared to conventional products

[Test conditions]

・Location: Winter tire test course

・Size: 195/65R15 91Q

・Vehicle used: Toyota Corolla HB (with ABS)

・Engine capacity: 1800 cc

・Driving system: 4WD

・Rim: 15x6

・Tire pressure: 250 kPa/240 kPa

・Road type: Icy road surface

・Testing method: Measure the distance when driving straight at a speed of 20 km/h between the brake being fully applied and the vehicle coming to a complete stop.

- *This test is conducted on an ice-covered road so performance may vary depending on the environmental conditions.

Ultimate driving enjoyment and a diverse range of mobility-related lifestyles

Our fundamental purpose is to support rich, high-quality mobility-related lifestyles by developing technologies and commercializing products that offer ultimate driving enjoyment and exquisite design features, while also fulfilling basic tire performance and sustainability requirements.

We are expanding the range of products on offer in our pillar OPEN COUNTRY series to address the diversifying needs of users in the SUV market in Japan.

The OPEN COUNTRY R/T TRAIL that we introduced for the Japanese market in March 2025 is a rugged terrain tire that sits between mud-terrain tires designed for full off-road use on uneven or muddy terrain and all-terrain tires that focus on achieving a good on-road/off-road balance. Being the first company to develop a pattern design for this tire category is a unique strength that sets us apart from other competitors. The tire offers both impressive designability and a high degree of comfort thanks to high traction performance and noise suppression qualities acquired using pattern technology refined through participation in off-road races. Furthermore, the bead wire and other components have been made from race-verified sustainably recycled materials. At the BAJA1000 held in Mexico in November 2024, TEAM JAOS competed in a LEXUS LX equipped with these tires and won its class in the Stock Full Size category.

The OPEN COUNTRY H/T II released in April 2025 offers quiet, fuel-efficient performance for on-road driving on paved roads and highways, while also carefully heeding the need for exemplary designability.

【TOPIC】

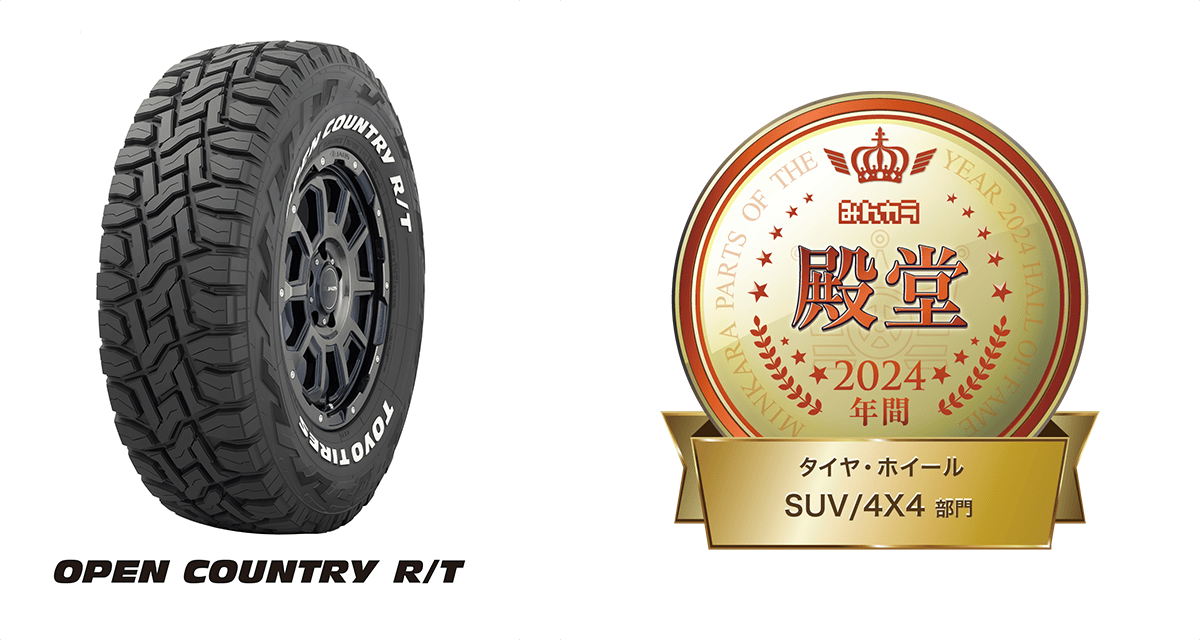

OPEN COUNTRY R/T receives Minkara PARTS OF THE YEAR 2024 Hall of Fame Award (SUV/4X4 tire category) for the third year in a row*6

Operated by LY Corporation, Minkara (short for “Everyone’s Car Life” in Japanese) is one of Japan’s largest specialist automobile social media platforms where car lovers post and discuss various car-related topics. Minkara aggregates the number of parts user reviews and the scores, and ranks parts with the highest support in its PARTS OF THE YEAR survey announced twice a year in the middle and the end of the year. OPEN COUNTRY R/T has been in the top rankings since the 2017 first-half awards, and was inducted into the Hall of Fame for the first time at the 2022 annual awards. 2024 marks its third consecutive year in the Hall of Fame. Going forward, we will continue to accurately grasp market trends and attentively incorporate user insights to help develop highly unique and attractive products.

- *6 This award is presented for parts that have garnered unwavering support in PARTS OF THE YEAR rankings over the past several years.

Providing value for evolving mobility in a changing society

As society changes and mobility technology advances with a wider use of IT and data and development of autonomous vehicles, we are beginning to see how the mobility landscape is reshaping. We are committed to developing technologies, products and services to provide safety that meets the needs of the evolving mobility environment.

Maintenance-free airless tires

A likely effect of changes such as self-service gas stations, home charging of EVs and wider adoption of car sharing is that there will be fewer opportunities for drivers to get tires serviced by experts. Also, cars need to be lighter in order to save energy and resources, and tire manufacturers face the challenge of providing safety in the next generation of mobility without the need to carry a spare tire. We aim to use airless tires to create maintenance free tire solutions with no need for a spare tire.

Our “noair” airless concept tire achieves the level of durability and maneuverability close to that of pneumatic tires and can be fitted on passenger vehicles for driving. As part of the path to commercialization, we are currently trialing the “noair” tires on last-mile delivery vehicles.

We also provided electric cart vehicles equipped with “noair” tires as mobility vehicles designed to shorten the time spent moving about the venue for people involved in the holding and operation of the 2025 International Exposition, and to help make the whole process more efficient. We are conducting demonstration experiments and improving performance for practical use in areas such as green slow mobility, while remaining attentive to any legal and regulatory trends related to driving on public roads.

Demonstration experiments

“noair” airless concept tire