Continue innovating next-generation mobility technology

- Challenges

- Our policy

- Our goal

- Responsible executive (as of April 2024)

- Organizational responsibilities (as of April 2024)

- Grievance mechanism

- Discovery Channel× TOYO TIRES Technology

- Creating recycling technologies for products and raw materials

- Supporting safe driving (improving safety awareness through data)

- Enforcing intellectual property strategy

Challenges

- Developing products, materials and technology for a society of next-generation mobility

- Creating recycling technologies for products and raw materials

- Innovating low-impact alternatives to substances of concern (eliminating microplastics, etc.)

- Supporting safe driving (improving safety awareness through data)

- Enforcing intellectual property strategy

Relevant stakeholders

- Direct: Customers (consumers), suppliers, employees, research bodies

- Indirect: Shareholders and investors, creditors, local communities, NGOs, industry groups

Our policy

The Toyo Tire Group believes that the value we provide through our products and services must support the evolution of mobility required for a new age. We will continue to challenge technological innovation to help build a society that exists in harmony with the environment and supports safe driving.

Our goal

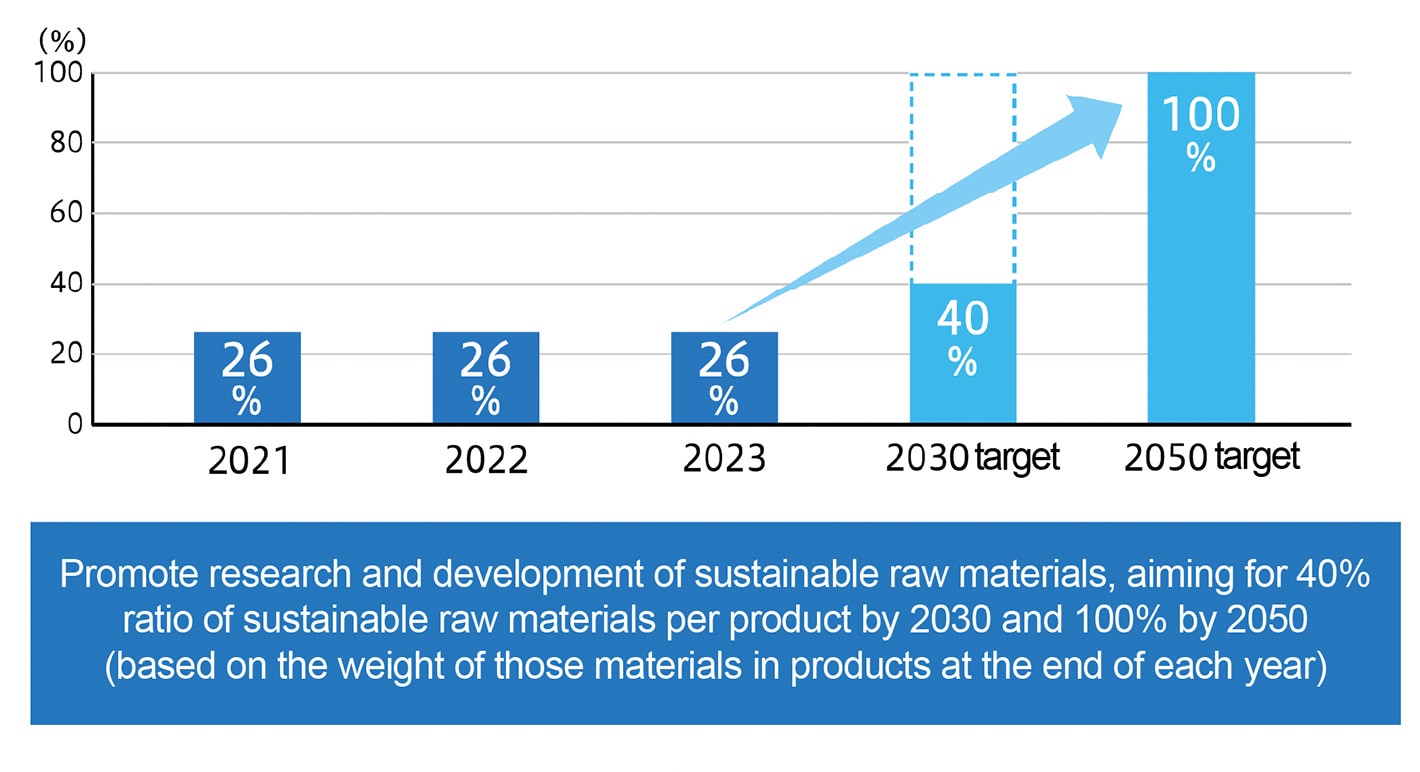

Our goal is to increase the ratio of sustainable materials*1 to 40% by 2030 and 100% by 2050.

- *1 Sustainable materials are defined by Toyo Tire as recycled and renewable raw materials.

Responsible executive (as of April 2024)

Director, Corporate Officer and Vice President of R&D Headquarters

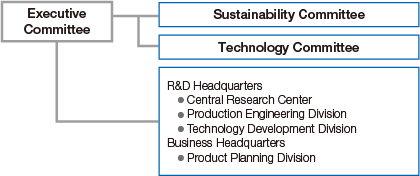

Organizational responsibilities (as of April 2024)

R&D Headquarters is responsible for promoting initiatives in this area. The Technology Committee oversees all initiatives and reports on progress to the Sustainability Committee.

Grievance mechanism

- Reporting hotline (whistle-blowing system): For executives, employees and suppliers

- Customer Relations Department: For customers (consumers) and local communities

- Online inquiry form: For customers (consumers), shareholders and investors, and NGOs

Discovery Channel × TOYO TIRES Technology

Creating recycling technologies for products and raw materials

We believe it is our mission as a manufacturing company to help promote the transition from a society that consumes resources to a society that circulates resources. We conduct research and development with the aim of increasing the ratio*2 of sustainable raw materials*3 used in our products to 40% by 2030, and 100% by 2050. That ratio reached 26% at the end of 2023.

By 2025, the Group plans to gradually introduce products made from recycled raw materials, such as recycled rubber made from used tires and recovered carbon black (rCB). Furthermore, we are developing technologies to increase the use of renewable raw materials, such as synthetic rubber made from biopolymer biomass (biomass-derived butadiene rubber and biomass-derived styrene butadiene rubber). This would lead to a reduction in the amount of petroleum-derived raw materials used, which have a large impact on climate change, and help reduce GHG emissions over the tire lifecycle.

- *2 The ratio is based on the weight of sustainable raw materials used in products at the end of each year.

- *3 Toyo Tire Corporation defines sustainable raw materials as recycled raw materials and renewable raw materials.

| Recyclable | rCB | Recycled steel cord | Recycled bead wire |

|---|

| Renewable | Biomass-derived synthetic rubber |

Plant-derived oil | Rice husk ash silica |

|---|

Ratio of sustainable raw materials: targets and actual results

[TOPICS]

1 Developing concept tires made from 90% sustainable raw materials

In January 2024, Toyo Tire Corporation developed a concept tire made from 90% sustainable raw materials. That represents a dramatic increase compared to the previous highest ratio of sustainable raw materials in our tires of 50%*4.

The concept tire was made from approximately 60% renewable raw materials, including biomass-derived butadiene rubber, biomass-derived styrene butadiene rubber, rice husk ash silica, plant-based oil, and biomass-derived polyester fiber, and roughly 30% recycled raw materials, including the butadiene rubber derived from CO₂ that we successfully developed together with the University of Toyama, rCB, recycled bead wire and recycled steel cord.

Another impressive feature of the tire is its ability to minimize the rolling resistance co-efficient, which greatly helps reduce GHG emissions throughout the tire lifecycle and improves the cruise range of EVs. It achieved AAA-equivalent fuel efficiency, the highest level of rolling resistance in the tire labeling system*5.

Going forward, we will continue to perfect this tire’s technological innovation and press for early commercialization as a product that can help realize an era of sustainable mobility.

*4 Ratio of sustainable raw materials used in the OPEN COUNTRY M/T-R tire supplied and installed in vehicles participating in Dakar Rally 2024

*5 A voluntary industry standard established by the Japan Automobile Tyre Manufacturers Association, Inc.: JATMA. Tires that meet certain values on both rolling resistance and wet-grip performance are defined as “fuel-efficient tires.” The system encourages a clear labeling method (display method) that ensures consumers receive the appropriate information.

The concept tire was exhibited at the TOKYO AUTO SALON 2024 as a reference

The sidewall design is in the motif of “sustainable” and “electric”

2 Commencing joint research on sustainable raw materials with the University of Novi Sad, Republic of Serbia

Toyo Tire Holdings of Europe GmbH, our holding company in Europe, has concluded an industry-university partnership agreement with the University of Novi Sad in Serbia for the research and development of sustainable raw materials. As a company with a production base in Serbia, we intend to promote technology development in both Japan and Serbia through this partnership in the hope of contributing to educational policies in Serbia. The Faculty of Technology, to which the joint research group is affiliated, is internationally renowned, especially in the field of rubber technology. We have set a goal of increasing the ratio of sustainable raw materials used in our products to 40% by 2030 and 100% by 2050. We will start research and development of sustainable raw materials by utilizing the knowledge of the University, one of whose founding faculties is the Faculty of Agriculture, and the characteristics of the region.

In the future, we will promote the development of sustainable raw materials on a global scale while leveraging the results of research conducted through such partnership.

■ Details of joint research

Initiatives to facilitate the use of sustainable raw materials

(1) Development of renewable raw materials utilizing plants grown in Serbia

(2) Development of recycled raw materials derived from waste tires

3 Successful synthesis of butadiene rubber from CO₂ for the development of tires made from sustainable raw materials

Joint research conducted with the University of Toyama has resulted in the development of a catalyst that converts carbon dioxide into butadiene at a high yield rate, and the successful synthesis of butadiene rubber, which is one of the main raw materials for tires. Carbon dioxide is considered to be one of the main drivers of climate change that causes serious adverse impacts on the global environment. Our success in pioneering the natural synthesis of butadiene from carbon dioxide will help minimize our environmental impact (in terms of carbon dioxide emissions) during the production process, compared to existing petroleum-derived raw materials. Moving forward, we intend to proceed with the process of development for mass production and aim to put it into practical use by the end of the decade. We are also carrying out research and development on replacing other raw materials used in tires with sustainable materials.

Efforts to reduce TRWP

Tire and road wear particles (TRWP) are dust produced by friction between the tire and the road surface that is a mixture of tire tread and road paving materials. Since the dust is discharged into the atmosphere, tire manufacturers view the need to reduce TRWP as a key issue. Any wear on tires does impact safety, comfort and fuel efficiency, so we are always striving to improve wear resistance through materials development and improved tread design. For example, we successfully improved wear resistance by designing an optimal compound polymer nanocomposite (rubber with highly uniform carbon black dispersion). This was achieved through advanced nanofabrication using Nano Balance Technology, our fundamental material design technology.

We also actively participate in industry groups, the Tire Industry Project (TIP)*6 and JATMA, to conduct research and study ways to mitigate the impact of TRWP since there are still many things about TRWP that have yet to be determined. We will continue to contribute to the industry’s efforts in this area, while also using any knowledge we acquire though these industry-wide activities to improve our own initiatives on reducing TRWP.

- *6 One of the sector projects of the World Business Council for Sustainable Development (WBCSD)

Supporting safe driving (providing data to ensure driver safety)

Tires are the only components of a vehicle that actually come into contact with the road surface, and we are developing sensing technology that can collect various types of information from tires. The concept we are working to take forward is to create new added value by turning tires into data acquisition devices. Using this technology, we developed a software application that processes data inputs from sensors attached to tires to derive the limits of the required tire performance, uses them to determine whether the tire force*7 of the running tires is within the performance range required for the road conditions, and provides real-time display. We are currently working to improve sensing accuracy by taking measurements of road surfaces under a range of conditions and proving the concept by testing the application on driving tracks. We will continue developing these technologies to serve as a part of safety systems required for autonomous driving.

- *7 Tire force is a term we use to describe the real-life tire performance, as estimated from data inputs from the tire such as air pressure, temperature, identified road surface condition, load, wear, and any anomalies detected.

Intellectual property strategy

We pursue technological innovation and product development designed to realize an environmentally friendly society and an era of safe mobility. However, we believe that the new technologies and products we create through these initiatives only truly acquire social value when they are delivered into the hands of our customers and put to use. We acquire the intellectual property rights that underpin the technical support required to enable the safe use of the products that result from our research and development into recycled raw materials, renewable raw materials, fuel-efficient rubber compounds and other areas. We believe that these ongoing intellectual property initiatives will help create value for the future era of mobility, and also secure our own presence in that arena.

At Toyo Tire Corporation, we develop technologies for practical application that meet the needs of our customers and clients, and that incorporate feedback from our production and sales divisions. Each year we hold the company-wide Technology Development Presentation to report to top management and announce our latest technological developments and the results of those initiatives.

In 2023, the presentation was held online and assessed entries based on the five perspectives of originality, rationality, future potential, development speed, and presentation. This initiative will be continued in the future as we further our technological developments to continue responding to the needs of society.

2023 Awarded Topics

Outstanding Technological Development Award

Virtual development for battery electric vehicles (BEV)

Original Equipment Manufacturers (OEMs) are investigating the introduction of virtual development to save vehicle development costs and resources and reduce development time. With virtual development, the entire development process from prototyping to performance evaluation is conducted virtually and analytically without a prototype by simulating an evaluation environment (tires, vehicles, road surfaces). Noise performance is a high priority for BEV tires, and is a factor highly prioritized by OEMs. We have developed a technique to decompose noise in the high-frequency range into “pattern-derived acoustic input” and “acoustic transmission by tracheal tubes,” and predict noise characteristics based on the results of pattern scanning analysis and acoustic computer aided engineering (CAE).

Unique Award

Improvements to wet grip / rolling resistance balance using silica interface control technology

Wet grip performance, a typical property of tires, is a trade-off with rolling resistance. It is necessary to identify and control the material structure that affects each property in order to develop higher performance tires by balancing grip and rolling resistance. We have succeeded in developing a new compound which can be used with nanoscale structural analysis technology developed by Nano Balance Technology, our proprietary platform technology, to predict the optimal interface structure and dispersion of silica, a reinforcement material used in rubber.

Surprise Award

Initiatives to achieve 100% sustainable materials in tires

In an effort to achieve a sustainable raw materials ratio in our tires (40% in 2030, 100% in 2050), we have developed a motorsports tire with a 50% sustainable raw material ratio and a concept tire with a 90% sustainable raw material ratio. For the motorsports tire, which has the off-road performance required for driving in harsh environments, we used a processing method control and MI technology to increase the ratio of sustainable raw materials. For the concept tire, which has achieved AAA-equivalent rolling resistance, we used proprietary sustainable raw materials (such as CO₂-derived butadiene rubber) to increase the ratio of sustainable raw materials as far as we could.

Sustainability

- Message from the President

- TOYO TIRE Value creation

- TOYO TIRE Sustainability

-

TOYO TIRE Materiality

- Help create a society of sustainable mobility / Support the enjoyment of mobility for all

- Support diverse talent with motivating challenges and job satisfaction

- Continue innovating next-generation mobility technology

- Pursue decarbonization in all corporate activities

- Promote supply chain sustainability

- Ensure the fundamentals of manufacturing: quality and safety

-

ESG Activities

- E: Environment

- S: Upholding human rights

- S: Managing occupational health and safety to global standards

- S: Crisis management (responding resiliently to natural disasters, infections and other crises)

- S: Working with local communities (Helping solve local issues)

- G: Sound governance

- G: Compliance

- G: Risk management

- G: Information security

- G: Promoting digital transformation (borderless and centralized business management through ERP reform)

- External Recognition

- Report Library

- ESG Data

- ESG Data/Survey Index

- GRI Content Index

- Communication on Progress (CoP) Index

- Editorial Policy