Promote supply chain sustainability

- Challenges

- Our policy

- Responsible executive (as of April 2023)

- Action promotion system (as of April 2023)

- Grievance Mechanism

- Procuring sustainable natural rubber

- Implementing supplier management

- Responding to conflict minerals risks

- Promoting efficient logistics

Challenges

- Procuring sustainable natural rubber

- Implementing supplier management and responding to conflict minerals risks

- Promoting efficient logistics

Relevant stakeholders

Direct: Suppliers, local communities

Indirect: Shareholders and investors, creditors, industry groups

Our policy

The Toyo Tire Group has established the Toyo Tire Group Basic Purchasing Policy and seeks to secure the appropriate product quality and price through fair transactions. Based on the Toyo Tire Group CSR Procurement Guidelines and the Sustainable Natural Rubber Procurement Policy, we work with our suppliers to promote sustainable procurement, with the goal of mitigating, preventing, and minimizing the negative impacts of our corporate activities on the environment and society. Together, we also aim to improve our corporate value and competitiveness. Moreover, we help create sustainable logistics by improving the productivity and efficiency of truck transportation and ensuring safe cargo handling operations.

Toyo Tire Group Basic Purchasing Policy

- Compliance

Comply with applicable laws, regulations, and social norms and strictly maintain confidentiality in all purchasing activities. - Partnership

Build and maintain an honest, healthy, and cooperative relationship with suppliers as equal partners.

Aim for mutual growth and development through enhanced communication and stronger bonds of mutual trust. - Transparent and fair trade

When selecting suppliers, assess them from a comprehensive standpoint that takes into account their willingness to share and collaborate on CSR initiatives as well as on quality, price, delivery, and sustainable supply capacity. - Environmental responsibility

Promote purchasing activities that also aim to reduce impact to the global environment.

TOYO TIRE Group CSR Procurement Guidelines

Policy on Sustainable Natural Rubber Procurement

Responsible executive (as of April 2023)

Corporate Officer and Vice President of Business Headquarters

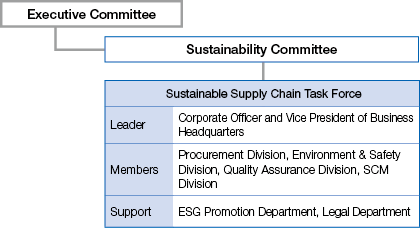

Action promotion system (as of April 2023)

The Sustainable Supply Chain Task Force, established under the Sustainability Committee, discusses action plans, targets, and KPIs related to ESG issues in the supply chain, while the Sustainability Committee regularly checks and monitors the status of these activities.

Grievance Mechanism

- Reporting hotline (whistle-blowing system): For executives, employees and suppliers

- Customer Relations Department: For customers (consumers) and local communities

- Online inquiry form: For customers (consumers), shareholders and investors, and NGOs

- Consultation Desk for Compliance with the Antimonopoly Act: For employees

- Dedicated Natural Rubber Supply Chain Desk: For customers (consumers) and suppliers

Activities: Procuring sustainable natural rubber

It is essential to build a supply chain that supports sustainable procurement in order to maintain a secure and stable supply of raw materials. The securing of a stable natural rubber supply into the future is an important management issue for a business group like ours that uses natural rubber as the main raw material. The natural rubber industry is facing issues relating to deforestation at production sites and infringement of local residents’ rights. We recognize the importance of striving to solve these problems across the entire supply chain from production through consumption.

International cooperation for building the sustainable supply chain

There is a worldwide movement to realize the sustainable procurement of natural rubber. Toyo Tire Corporation is a member of the Global Platform for Sustainable Natural Rubber (GPSNR)* launched in 2018 under the leadership of the Tire Industry Project (TIP), which is part of the World Business Council for Sustainable Development (WBCSD). As a member, we participate in discussions designed to solve relevant issues. We are working to prevent deforestation, conserve biodiversity and water resources, respect human rights and support local communities, improve the productivity of natural rubber, and improve the transparency of our supply chain. We also exchange information with civil society sectors (NGOs, etc.) with specialized knowledge on environmental and social issues at natural rubber production sites.

Our aim going forward is to continue to cooperate with international initiatives and stakeholders and to build a sustainable natural rubber supply chain across our whole value chain.

- * A platform that seeks to transcend industrial boundaries and ensure that the production and use of the world’s natural rubber is carried out in a way that is more socially and environmentally conscious

Promoting sustainable procurement

Based on the guidelines for incorporating GPSNR’s Principles of Sustainable Natural Rubber into our business activities as a tire manufacturer, we conducted a thorough review of the themes related to natural rubber procurement that had been defined as part of our CSR Procurement Guidelines. From 2021, we strengthened our implementation through a separate Sustainable Natural Rubber Procurement Policy.

That policy is designed to improve the effectiveness of initiatives relating to healthy ecosystems, human rights, and communities, etc.

Currently, in addition to conveying this policy to suppliers and asking for their cooperation, we have launched various activities such as forming contracts with suppliers and exchanging information with environmental NGOs to ensure a level of traceability that complies with the activity plan prescribed by our Supply Chain Task Force.

We have also set up a dedicated contact point specifically for the natural rubber supply chain. We received no reports in 2022.

We will continue to cooperate with international initiatives and stakeholders to build a sustainable natural rubber supply chain.

Activities: Implementing supplier management

Engaging suppliers through guidelines

We have formulated the Toyo Tire Group CSR Procurement Guidelines and request all suppliers to pursue activities in accordance with these guidelines to help address environmental and social issues across our entire supply chain from production through consumption. We are also appealing to our suppliers to help convey the purpose and nature of these guidelines further up the supply chain.

The guidelines are reviewed whenever there is change in social demands or the business environment. We have published the guidelines in Japanese, English, and Chinese as we expand our global procurement.

From 2022, we entered into a new agreement with EcoVadis, a third-party CSR rating agency in France, and outsourced the CSR rating of our suppliers to EcoVadis in order to objectively assess the environmental and social risks of our supply chain. We assess risks based on the results of a fair and objective survey conducted by EcoVadis expert analysts, engage with our suppliers, and work together to address issues in the supply chain. We will gradually expand the scope of the survey starting with our natural rubber suppliers, and aim to complete the survey of all suppliers by the end of 2025.

In addition, we have been conducting our own questionnaire survey on decarbonization of existing suppliers since 2021. We will also continue working to address issues to reduce the environmental impact of our supply chain.

Whistle-blowing system

Toyo Tire Corporation operates a whistle-blowing system that can also be utilized by suppliers, and conveys information to suppliers through briefing sessions on the CSR Procurement Guidelines and other venues. There were no reports from suppliers in 2022.

Fair and transparent transactions, and thorough compliance

We declared our commitment to free competition and fair trade in each country and region in the Toyo Tire Group Code of Conduct. We comply with antimonopoly and subcontracting laws, pursue fair procurement activities, comply with import- and export-related laws and regulations, and ensure proper labeling and product descriptions.

We ensure that our business activities are based on fair and free competition by establishing purchasing regulations that stipulate thorough implementation of fair and non-discriminatory business dealings and prohibit the development of personal interests with suppliers. We have also established anti-cartel regulations to prevent cartels and bid-rigging activities that are prohibited under antimonopoly laws or any action that could be construed in such a way.

For purchasing transactions, we continue to independently monitor the status of compliance with the subcontracting law using a checklist prepared together with the Procurement Division, Legal Department and Compliance Department. The checklist is used to check whether the subcontracting law applies and if so, whether there are any omissions in the documentation and statements that have to be prepared and stored. We also use e-learning platforms to regularly conduct seminars on subcontracting law and other regulations. These initiatives help promote information sharing within the Group, increase the knowledge of staff responsible for subcontracting transactions, and ensure a consistent level of understanding among them.

To prevent any fraud or bid rigging caused by contact between suppliers’ staff responsible for procurement and to reduce bidding costs, the Group has introduced an electronic bidding system for selecting suppliers and has engaged in fair procurement activities at major purchasing sites around the world.

Activities: Responding to conflict minerals risks

Conflict minerals response

The purchase of conflict minerals (tin, tantalum, tungsten and gold) and cobalt mined in conflict areas or high-risk areas may be used as a source of funds for local armed groups, or may encourage corrupt practices such as human rights violations, bribery, and money laundering. In Europe and the U.S., manufacturers are legally obliged to conduct due diligence throughout their supply chains. In such areas, our Group policy is to procure mined and manufactured minerals and raw materials that have not been involved in any human rights violations, environmental destruction, conflicts, or corruption. We enlist the cooperation of suppliers to trace the raw materials we purchase back to the smelters in order to ensure that they are not linked to such inhumane acts. If there are any concerns of involvement, we will demand corrective action through our suppliers.

Activities: Promoting efficient logistics

Relevant stakeholders

- Direct: Suppliers, local communities

- Indirect: Shareholders and investors, creditors, industry groups

Responsible executive (as of April 2023)

Corporate Officer and Vice President of Business Headquarters

Efficient logistics promotion task force system (Promoting efficient logistics)

We have set up a task force led by the General Manager of the SCM Division and are working with the managers of six logistics bases in Japan.

Grievance mechanism

- Reporting hotline (whistle-blowing system): For executives, employees and suppliers

- Customer Relations Department: For customers (consumers) and local communities

- Online inquiry form: For customers (consumers), shareholders and investors, and NGOs

Initiative: Improving transport productivity and creating better working conditions

With the serious shortage of truck drivers in Japan, initiatives to improve the productivity and efficiency of truck transportation and create better working conditions for drivers are being advanced under the White Logistics Movement led by the Ministry of Land, Infrastructure, Transport and Tourism.

As an initiative to support the movement, the Toyo Tire Group is implementing modal shift — switching to ships, national railways and large trailers — of long-distance transportation of goods dispatched from our factories in Japan. We have already completed the switch of more than 50% of long-distance truck transportation, and aim to reduce this to about half of the 2022 rate in 10 years. Furthermore, by ensuring greater safety in cargo handling operations, we not only reduce the burden on drivers, but also help create job satisfaction and economic growth.

Specific initiatives

We have set a goal of reducing the percentage of long-distance transportation by truck in Japan from factories and ports to our regional warehouses and customers’ warehouses by 20% by 2025 (compared to 2020). We are also conducting risk assessments at all logistics bases in Japan with the aim of halving the number of accidents or certain near-miss incidents relating to cargo handling. We hold regular meetings to introduce modal shift examples at each site as well as accidents and certain near-miss incidents and encourage people to share their opinions to help promote progress and achieve our targets.

- Introduced and expanded large container transportation by national rail from Sendai and Kuwana Logistics Centers

- Introduced a large trailer transportation method that reduces the burden on the driver by changing drivers at transit points

- Installed safety fences in our Sendai and Kuwana Logistics Centers’ warehouses following a risk assessment (to prevent tire racks from toppling or items from falling in the event of an earthquake)

- Installed surveillance cameras for safe work operations and for safe forklift driving operations inside factory logistics centers and domestic distribution centers

Action for Sustainability

- Message from the President

- TOYO TIRE Value creation

- TOYO TIRE Sustainability

- TOYO TIREʼs SDGs

-

TOYO TIRE Materiality

- Help create a society of sustainable mobility / Support the enjoyment of mobility for all

- Support diverse talent with motivating challenges and job satisfaction

- Continue innovating next-generation mobility technology

- Pursue decarbonization in all corporate activities

- Promote supply chain sustainability

- Ensure the fundamentals of manufacturing: quality and safety

-

Sustainability and ESG themes beyond the material issues

- E: Environment

- S: Upholding human rights

- S: Managing occupational health and safety to global standards

- S: Crisis management (responding resiliently to natural disasters, infections and other crises)

- S: Working with local communities (Helping solve local issues)

- G: Sound governance

- G: Compliance

- G: Risk management

- G: Information security

- G: Promoting digital transformation (borderless and centralized business management through ERP reform)

- Toyo Tire Group Charter of Corporate Behavior

- Toyo Tire Group Code of Conduct

- Site Report

- Report Library

- Editorial Policy

- GRI Content Index

- ESG Data/Survey Index

- Communication on Progress (CoP) Index

- External Recognition