S: Managing occupational health and safety to global standards

- Challenge

- Our policy

- Targets

- Responsible executive (as of April 2024)

- Organizational responsibilities (as of April 2024)

- Grievance mechanism

- Main resources for promoting activities (2023)

- Creating safe workplaces

- Promoting health management

- Creating disaster-resistant workplaces

Challenge

- Managing occupational health and safety to global standards

(Mentally and physically safe and healthy working environments for all stakeholders)

Relevant stakeholders

Direct: Employees

Indirect: Local communities, shareholders and investors, creditors, industry groups

Our policy

Under the direction of senior executives, we implement the necessary measures based on risk assessments of our corporate activities and promote Group-wide occupational health and safety management, with labor and management working together to operate a system based on Guidelines on Occupational Safety and Health Management System (OSHMS Guidelines) developed by Japan’s Ministry of Health, Labour and Welfare. In addition to current work and facilities, we also conduct risk assessments for changes in their conditions and new work and facilities, and implement safety measures based on the results.

We believe that it is our responsibility to all our stakeholders to give safety our top priority, and ensure safety in all of our corporate activities.

Furthermore, the Group seeks the happiness and job satisfaction of our employees, and is committed to a health management policy of providing a healthy work environment and protecting their mental and physical health to support their performance growth.

2024 Occupational Health and Safety Policies

| Safety: | Build a true culture of safety at sites by fusing top-down and bottom-up approaches through leadership teams and small group activities |

|---|---|

| Disaster preparedness: | Work on fire prevention efforts with all employees participating, and improve preparation and training for fires and natural disasters |

| Health: | Ensure healthy labor conditions and good mental and physical health so that employees can achieve more while feeling positive and motivated |

Occupational health and safety management system certification (2024)

Total number of manufacturing bases: 17 sites

OSHMS: 3 sites in Japan

JISHA Good Safety Company: 5 sites in Japan

ISO 45001:4 sites in Malaysia, China, Taiwan, Serbia

China Work Safety Standardization certification: 4sites in China

Targets

FY2024 Zero lost-time accidents (as well as non-lost-time accidents)

Work to assess occupational health and safety conditions in the workplace based on frequency and severity rates of lost-time and non-lost-time accidents, details of fire outbreaks, and other data, to improve the work environment and reduce risks.

Responsible executive (as of April 2024)

Corporate Officer and Vice President of Quality Assurance, Environment & Safety Headquarters

Organizational responsibilities (as of April 2024)

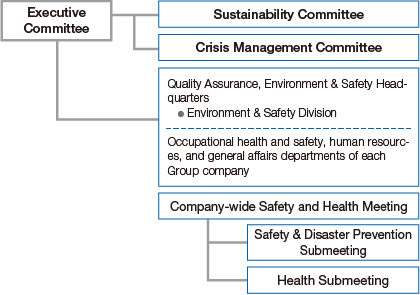

At the joint labor-management Company-wide Safety and Health Meeting, annual policies, targets, and plans for occupational health and safety are decided and plan progress is evaluated and improved. The results are reported to the Sustainability Committee.

The Environment & Safety Division is responsible for promoting occupational health and safety, and reports on important issues at the Company-wide Safety and Health Meeting, which is chaired by the Corporate Officer and Vice President of Quality Assurance, Environment & Safety Headquarters, and at the Executive Committee.

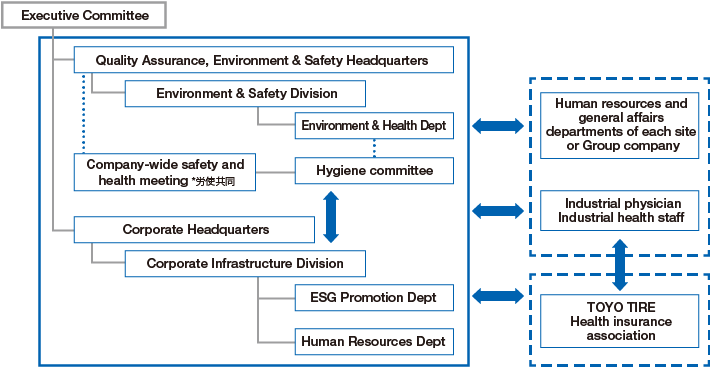

Health management promotion system

We promote health management as a company as a whole through a group-wide collaboration system centered on the quality, environment and safety management and corporate management, as well as personnel in charge of each site and experts in industrial hygiene and health.

Grievance mechanism

- Reporting hotline (whistle-blowing system): For executives, employees and suppliers

- Customer Relations Department: For customers (consumers) and local communities

- Online inquiry form: For customers (consumers), shareholders and investors, and NGOs

- Labor-Management Council Meetings: For employees

Main resources for promoting activities (2023)

- Qualified safety assessors*: 413 people in Japan

- * Staff in charge of sharing information with headquarters and promoting initiatives: Located at main manufacturing bases in Japan

- Safety education and training facilities: 6 sites

- Fire prevention inspectors: 626 people in Japan

- Health managers: 21 people in Japan

- Industrial physicians: 15 people in Japan

- * Employees possessing the knowledge and skills needed to evaluate machinery safety, and the overall ability to judge suitability.

Creating safe workplaces

We are working from the perspectives of equipment, personnel, and management structure development to create safe workplaces at all business sites.

For equipment, we promote safety by conducting hazard risk assessments, managing hazards through elimination, containment or interlock based on equipment safety standards, and providing personal protective equipment and ergonomic work environments.

In terms of personnel, we strive to reduce risks in order to eliminate accidents caused by human error, and improve and maintain awareness to change human behavior. Along with visualizing the residual risks that remain after improving equipment safety, we extensively manage them by indicating high residual risks, implementing operation standards, employing stop-call-wait, point-and-call and hazard prediction activities, and holding voluntary small-group activities for improvement. At manufacturing sites where employees with diverse backgrounds work, we make announcements in multiple languages and use illustrations and color-coded warning signs.

In the development of management structures, we are expanding occupational health and safety management systems, including ISO 45001, OSHMS, and GSC. We have compiled the Industrial Accident Response Manual for guiding prompt and adequate responses to prevent damage from spreading when labor-related accidents occur, with the aim of protecting employee safety and company credibility, and keeping personal and physical losses to a minimum. The manual stipulates specific steps for handling labor-related accidents, including the necessary risk management systems and procedures in normal times, as well as actions for employees to take and what to do in emergencies.

In Japan, a monthly meeting is held (currently online) between the Environment & Health Department and staff in charge of safety and disaster management at all sites. The meetings allow each site to share information on and horizontally deploy measures to prevent and mitigate disasters, thus preventing similar incidents from occurring at other sites.

We also strive to manage the health and safety of non-regular workers through steps such as distributing an on-site safety training text for those working at manufacturing sites in Japan under measures and methods managed by the Group.

[TOPIC] Employee contribution to initial firefighting

A forest fire broke out on private land adjacent to land owned by Ayabe Toyo Rubber Co., Ltd., one of our subsidiaries. On May 26, 2023, Ayabe City Fire Department presented the company with a letter of appreciation for the firefighting activities of 17 employees who worked to extinguish the fire when it first broke out.

Employees engaged in transportation-related work outdoors noticed something unusual and called the fire department. They also notified those concerned and worked to extinguish the fire using fire extinguishers and by relaying buckets of water.

Luckily none of the employees who got involved were injured or burned as they contributed to the local community by putting into practice the things they had learned during annual disaster prevention drills and fire extinguisher handling training.

We will continue to train our employees to be prepared for fires and natural disasters so that they are ready to play their part and take appropriate action should a disaster occur.

2023 Safety performance

Lost-time accident frequency rate at manufacturing bases (number of lost-time accidents per million hours worked)

Japan: 0.09 (0.27 in 2022)

Outside Japan: 0.10 (0.43 in 2022)

- Note: Rubber product manufacturing industry average in Japan is 0.58.

See the results from 2019-2023 here

Improving our safety training program

Each Toyo Tire Group base conducts training following a level-specific safety education system. We are focusing on improving our hazard prediction (known as kiken yochi, or KY, in Japanese) training and hands-on learning. We have thus set up Safety KY Training Halls at six business sites (as of the end of 2023) where employees are taught the importance of working according to rules through hands-on experience of the dangers of equipment, using machines for educational purposes.

We additionally use data on past accidents and near misses at each base to analyze accident trends, and use the findings to improve and enhance the effectiveness of safety measures and educational programs. For safe handling and management of chemical substances, we distribute safety data sheets (SDS) for raw materials to concerned bases and conduct training at each base. We are also improving the education of employees authorized to perform non-routine hazardous tasks with high risk of accident, as well as educating safety assessors and training qualified personnel at equipment planning and design departments and plant equipment management departments. At the end of 2023, there were 413 certified employees.

Promoting health management

The Toyo Tire Group views the management of employee health from a business perspective and supports the idea of strategic health management.

Toyo Tire Group’s Commitment to Health

The Toyo Tire Group is committed to maintaining the physical health and mental well-being of every employee as a necessary condition to realizing our Philosophy.

Being a company where employees work in a healthy environment is to ensure that we continue to reliably provide value to wider society.

Takashi Shimizu

Representative Director, President & CEO

Toyo Tire Corporation

We have been focusing on greater prevention of mental health issues, which are the main cause of long-term absences.

For example, as part of work engagement efforts and building the basic foundation for health management, in Japan we provide mental health care seminars for all employees, from managers and supervisors to general staff, as well as e-learning for mental health. To better understand employee health issues and investigate necessary measures, we have also been conducting stress checks at all business sites in Japan even before it became required by Japan’s Industrial Safety and Health Act. Over 90% of employees undergo a check each year, and we are analyzing the collective results to help improve working environments.

As a specific measure to promote mental and physical health in our employees, we are offering an employee assistance program and promoting early detection and counseling through individual guidance and consultation in cooperation with industrial health staff. Through this measure, we aim to reduce long-term absences.

To support a smooth return for employees after a long-term absence, we are reviewing our return-to-work support measures so that we can provide the right assistance for each case according to the employee’s physical and mental condition.

At the end of 2021, we set specific targets for reducing our number of smokers. From January 2022, we designated the 22nd of every month as a non-smoking day, and from January 2023, we set a weekly non-smoking day to provide further opportunities for behavioral change in our employees. Furthermore, in January 2024, we introduced a total ban on smoking during working hours and we are working to reduce opportunities to smoke.

We are also working on the following as part of our efforts to improve internal communications.

- We conduct employee opinion surveys to bring out the opinions of employees, identify issues for organizational management, formulate and implement action plans at every organizational layer – department, division, and headquarters, and thereafter monitor their progress company-wide. (Survey conducted every two years)

- Since 2020, we have been taking stock of work tasks and streamlining operations to promote an organizational structure that does not require overtime throughout the company. (Company-wide overtime work hours decreased from 2019 level)

- For employees posted overseas, we conduct pre-assignment training to raise awareness of workplace safety measures and provide cross-cultural communication and required language training for interacting with local supervisors and subordinates, as well as conduct post-assignment health checkups. We also provide the necessary training for employees on overseas business trips based on the above.

To cope with infectious or contagious diseases in a way that mitigates damage, protects the safety of employees, and minimizes the occurrence of risks, our Group Infectious and Contagious Disease Response Manual stipulates the necessary crisis management system and procedures in normal times, as well as actions for employees to take and what to do in emergencies.

Finally, heat stroke while on the job has emerged as a new occupational health and safety risk in recent years, and we take measures to control the climate in workplaces, as well as strongly encourage employees to hydrate regularly. Our special subsidiary Showa Estate Co., Ltd. has taken steps to both prevent infection and heat stroke, such as by introducing a uniform that dries quickly and feels cool against the skin to reduce the stress of employees while cleaning outdoors, where they are more susceptible to high temperatures.

The Group participates in joint research activities with other companies and conducts health management initiatives throughout the year. We share the outcomes of these activities with other companies, including those working on initiatives other than health management, in order to help expand the reach of health management promotion activities.

Request to business partners

Matters to be observed and considered in relation to health management

- Compliance with laws and regulations related to occupational safety and health

- Establishment of an occupational safety and health environment

- Implementation of mental health measures

- Promotion of health management measures

- Implementation of measures to prevent excessive work (appropriate management of working hours, etc.)

- Promotion of work-life balance for childcare, nursing care, etc.

[TOPIC] Participation in the Health & Productivity Management Alliance

We have participated in the Health & Productivity Management Alliance as part of our efforts to further promote and enhance corporate health and productivity management. The Health & Productivity Management Alliance was established by eight companies from different industries aiming to promote health and productivity management at companies and achieve a healthy society. The Alliance is working to improve the foundations of health and productivity management by sharing individual activities and solutions across industries.

Key measures, KPIs and performance

We created a health management strategy map, identified the management issues that we need to address through health management, and have been working on various measures.

Mental health measures

We provide support to employees returning to work from leaves due to mental conditions, which accounts for over 60% of company leaves. At the same time, we are also working to improve our stress check analysis to ensure that we implement effective measures to prevent further cases from developing.

See the results from 2019-2023 here

• Programs

- (1) Stress check (FY2023)

- - Test rate: 95.8%

- - High stress rate: 8.7% for engineering and administrative staff, 19.7% for production staff

- (2) Organizational reform initiatives based on stress check group analysis results

- - Mental health seminars for health promoters (organized by department responsible for health management promotion)

- - Mental health seminars at sites (organized by health promoters at sites)

- - Appointment of an outside counselling service

- - Active intervention at Group companies with high rates of absenteeism

- (3) Introduction of presenteeism metrics

Smoking measures

On the occasion of the full enforcement of the revised Health Promotion Act of Japan in April 1, 2020, we closed down indoor smoking areas and enforced other measures to stop smoking. Together with stepping up our efforts against smoking and taking measures to combat secondhand smoke, we are also working to foster a work environment that accounts for health hazards.

See the results from 2019-2023 here

• Programs

- (1) Non-smoking day: Gradually reduce opportunities to smoke and foster a work environment that discourages smoking

- - 2023: Set one day each week as a non-smoking day

- - 2024: Total ban on smoking during work hours, strengthened efforts to reduce opportunities to smoke

- (2) Stop smoking support program (in collaboration with the Health Insurance Association)

- - Provide a “quit smoking program” (aids to stop smoking, stop-smoking clinics, etc.)

- (3) High-risk approach

- - Provide health guidance to smokers through counselling

Lifestyle-related disease measures

With the increase in remote work opportunities, we have seen a downward trend in the practice of healthy habits* by individuals. We are therefore enhancing measures aimed at improving lifestyle habits. Here, we focus on proper weight maintenance rate, which is affected by all lifestyle habits. (* See “Breslow’s seven health habits” for more details on the practice of healthy habits)

See the results from 2019-2023 here

• Programs

- (1) High-risk approach

- - Recommend to see a doctor or face-to-face guidance by industrial physicians or public health staff based on the results of health checkups

- (2) Population approach

- - Step up number of seminars on diet (including alcohol consumption), exercise and sleep

Other achievements

See the results of other achievements here

Creating disaster-resistant workplaces

We have improved our Group fire prevention management, and used the experiences gained through the 2011 earthquake and tsunami and other major disasters to strengthen our initiatives for disaster preparedness and mitigation.

Each base engages in activities such as practical firefighting training and no-scenario earthquake drills, which are being held repeatedly to improve their effectiveness and increase participation. Firefighting training is conducted for hazardous materials in compliance with the National Fire Protection Association’s NFPA 600 standard. In Japan, we have held fire prevention inspector training since 2018, and 626 employees have participated as of 2023. One major fire was reported in 2023, but as a result of our continued efforts, we were able to achieve our target of keeping the number of fires to no more than two.

In regions outside of Japan, we are also engaging in measures and disaster preparedness drills according to the disaster risks of each area.

2023 Disaster prevention drills

Japan: 18 sites (4,556 total participants)

US: 1 site (239 total participants)

Asia (excluding Japan) and Oceania: 4 sites (1,162 total participants)

See the results of disaster prevention drills here

Cases of labor standards violations

There were no cases of labor standards violations in 2023.

Sustainability

- Message from the President

- TOYO TIRE Value creation

- TOYO TIRE Sustainability

-

TOYO TIRE Materiality

- Help create a society of sustainable mobility / Support the enjoyment of mobility for all

- Support diverse talent with motivating challenges and job satisfaction

- Continue innovating next-generation mobility technology

- Pursue decarbonization in all corporate activities

- Promote supply chain sustainability

- Ensure the fundamentals of manufacturing: quality and safety

-

ESG Activities

- E: Environment

- S: Upholding human rights

- S: Managing occupational health and safety to global standards

- S: Crisis management (responding resiliently to natural disasters, infections and other crises)

- S: Working with local communities (Helping solve local issues)

- G: Sound governance

- G: Compliance

- G: Risk management

- G: Information security

- G: Promoting digital transformation (borderless and centralized business management through ERP reform)

- External Recognition

- Report Library

- ESG Data

- ESG Data/Survey Index

- GRI Content Index

- Communication on Progress (CoP) Index

- Editorial Policy