Help create a society of sustainable mobility / Support the enjoyment of mobility for all

- Challenges

- Our policy

- Responsible executive (as of April 2023)

- Action promotion system

- Grievance mechanism

- Main resources for promoting activities (2022)

- Environmental contribution

- Safety

- Commercializing airless tires

- Ultimate enjoyment of driving and sophisticated features

Challenges

- Environmental contribution (CO₂ emissions reduction): Reducing tire rolling resistance, improving EV compatibility, saving resources

- Safety: Maintenance-free products, diagnosis of tire wear

- Commercializing airless tires

- Ultimate enjoyment of driving and sophisticated features

Relevant stakeholders

- Direct: Customers(consumers), suppliers, employees, research institutions

- Indirect: Shareholders and investors, creditors, local communities, NGOs, industry groups

Our policy

We know that the sustainable future for tire and automotive parts manufacturers will only be ensured once a society of sustainable mobility has been created. That’s why we are using our unique products and services to help establish a society of sustainable mobility that boasts net-zero environmental impact, zero accidents and efficient transportation.

In addition to providing the necessary elements for promoting sustainability, we believe that using our unique products and services to satisfy the various features that people expect from superior mobility life will create added value designed to support a diverse mobile society, so that is what we intend to do.

Responsible executive (as of April 2023)

Director, Corporate Officer and Vice President of R&D Headquarters

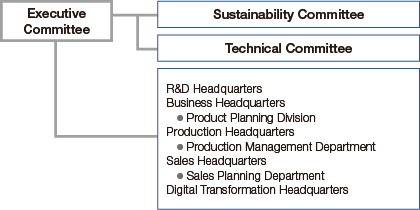

Action promotion system

Spearheaded by our R&D Headquarters, we are coordinating R&D, product planning, sales planning and digital transformation (DX) functions and promoting sustainability-related activities based on various themes that correlate with the aims of our medium-term business plan.

The Technical Committee oversees the overall implementation of those activities and reports progress to the Sustainability Committee.

Grievance mechanism

- Reporting hotline (whistle-blowing system): For executives, employees and suppliers

- Customer Relations Department: For customers (consumers) and local communities

- Online inquiry form: For customers (consumers), shareholders and investors, and NGOs

- n addition to the above routes, our technical service departments, Group sales companies and distributors also receive inquiries and complaints.

Main resources for promoting activities (2022)

- R&D expenses: 11,320 million yen *including 1,347 million yen for basic research expenses

- Expenses related to environmental conservation during R&D activities: 386 million yen

- Capital investment in rationalization, improving quality and enhancing production facilities: 47,303 million yen

- R&D bases: 5 bases (Japan, US, Germany)

- We are strengthening our unique technologies and developing differentiated products by encouraging cooperation between our R&D functions in Japan, the US and Europe. We also conduct joint research with multiple universities and research institutes.

Activities: Environmental contribution

Reducing the CO₂ emissions of vehicles is a challenging issue that needs to be addressed across the supply chain. At Toyo Tire Corporation, our goal is to help reduce greenhouse gas (GHG) emissions per tire by 20% by 2030 compared to 2019 levels. To cut CO₂ emissions of vehicles caused by running tires, we set the reduction of tire rolling resistance as a top priority and included improving the fuel efficiency grading of tires as a development requirement for product model changes. Taking life cycle assessment into consideration, we are also developing environmentally oriented products with better energy efficiency and resource savings.

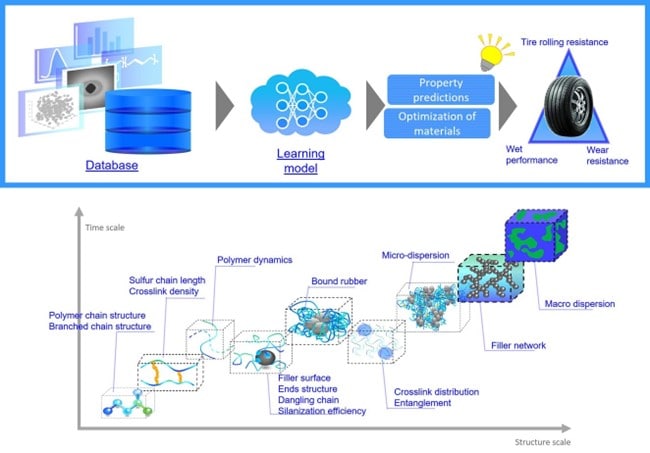

Advancements in fundamental rubber materials technology

We are seeing signs of rapid change in the area of materials development as AI and machine learning start to be employed. We have been engaged in continuously innovating Nano Balance Technology, our proprietary platform technology for rubber materials development. It includes technologies for predicting rubber material properties and aiding in composite design using materials informatics (MI).*1

Since 2018, we have been using our accumulated existing data assets to verify technologies predicting tire composition and physical properties using MI technology. To achieve high-performance product development while at the same time shortening development lead times and reducing costs, we have been working on creating an environment where we can make full use of our stored data for development work using prediction data and analysis methods from an entirely new perspective.

Currently, we are applying these data stores to actual development to help create differentiated products that fulfill multiple performance requirements to a high level. Those requirements include higher fuel efficiency and better wet-grip performance that can be achieved by using highly dispersed silica and new materials.

- *1 AI-driven technology that facilitates a more efficient exploration of new and alternative materials than conventional methods.

Building the technology for virtual development

We have been working on building the technology for virtual development by improving the accuracy of estimates of tire characteristics on paper and establishing an efficient workflow for assessing actual vehicles. In addition to using this technology for centralizing data management, improving the accuracy of estimates of basic dynamometer characteristics and constructing tire models, we are working to adapt it to other items for actual vehicle performance estimation. These initiatives enable shorter development periods as well as reduce the number of prototypes and actual vehicle assessments, thereby helping cut CO₂ emissions in the development process.

Developing weight reduction technology

We are developing weight reduction technologies and rolling out products for each category of tires for passenger cars, light trucks, and trucks and buses. To achieve our medium-term target of reducing tire weight, we have been working on reducing the thickness of components, considering new structures, and improving the work process capacities of our plants. In particular, we have already started developing products with weight reduction technology using high-precision equipment at our Serbia Factory last year, and plan to expand this initiative in the future.

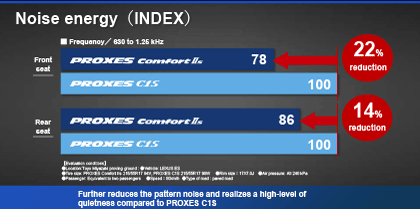

[TOPIC] PROXES Comfort IIs: Premium comfort tire developed in pursuit of superior cruising experience and advanced environmental performance

PROXES Comfort IIs is a premium comfort tire that was developed in pursuit of superior cruising experience and advanced environmental performance. Using our proprietary T-MODE tire design platform technology, we adopted an asymmetrical pattern in designing the tread in order to provide different functions within the tread pattern*2. By optimizing the pattern design on the inner and outer sides of the tire, we were able to reduce the noise energy generated by the tire pattern by 22% compared to our previous model (PROXES C1S), ensuring a high level of quiet comfort in the cabin interior. In addition, we increased the stiffness of tread blocks to improve steering stability and reduce drift when changing lanes, providing a balance between high-quality ride comfort and steering stability.

For material development, we developed a fuel-efficient compound using our platform technology for material design, Nano Balance Technology. We used a new silica dispersing agent to more evenly disperse silica, a material that effectively reduces rolling resistance and improves wet-grip performance and wear resistance, making it possible to achieve optimally high levels of performance for these features.

- *2 Grooves and incisions engraved on the tire tread.

Activities: Safety

Tire wear forecasting system to boost customer safety

The Technology Development Division and the DX Promotion Division are collaborating on an application that can diagnose tire wear based on information about the usage status of truck and bus tires. The teams are conducting trials by asking customers to try out the app so they can improve the accuracy of their predictions and expand the range of functions to facilitate the remote confirmation of air pressure and wear prediction results. This technology enables us to help improve the safety of drivers and passengers by encouraging customers to appropriately rotate their tires based on the wear predictions. We also expect it will have environmental benefits by extending tire life and increasing the possibility of reuse as retread tires.*3

- *3 A worn tire that is reused by replacing the rubber in the part of the tire that comes into contact with the road surface.

Achieving long product life and superior braking performance on wet surfaces

To develop technologies that protect the safety of customers by improving product life and superior braking performance on wet surfaces, we have been installing new facilities and modifying evaluation equipment with the aim of raising the level of tire measurement, analysis and evaluation technologies. We are working on visualizing the behavior of tires with tire wear and when braking on wet surfaces, and developing new design elements. The design elements we obtain from this process will be rapidly applied to our products to help ensure the safety of our customers.

[TOPIC] PROXES Sport 2: Premium sports tire delivering high levels of handling and braking performance

PROXES Sport 2 is a premium sports tire that delivers the high levels of handling and braking performance required of sports tires. An asymmetrical tread pattern* and compound are used to segment different functions and effectively improve braking and handling performance.

Silica, which contributes to rubber flexibility, is evenly dispersed in the compound at the inner side of the tread, allowing the tires to touch the ground in a supple manner on uneven road surfaces and improving grip performance on both wet and dry surfaces. Meanwhile, silica dispersion is controlled in the compound at the outer side to ensure rubber stiffness.

For its structural design, we adopted a new profile to optimize side deflection and control tire deformation when changing lanes or cornering. This helps improve handling performance on both wet and dry surfaces.

Activities: Commercializing airless tires

Our “noair” airless concept tire is designed to facilitate maintenance-free, no-spare solutions that satisfy the needs of the next-generation mobility society in which people opt for self-service gas stations, home charging of electric vehicles and more prevalent car sharing. In 2017, noair became the first tire in the industry to demonstrate a level of performance that enabled it to be installed and driven on a passenger vehicle by achieving a level of durability and maneuverability that is close to that of pneumatic tires. We installed the noair tires on golf carts and conducted test drive events in 2022 as part of our efforts to facilitate their practical use. We are paying close attention to the formulation of laws and regulations regarding airless tires as we consider installing them on futuristic mobility vehicles and using them in recycling operations.

Golf cart using “noair” tires

Golf cart using “noair” tiresActivities: Ultimate enjoyment of driving and sophisticated features

Toyo Tire Corporation’s unique strategy is to develop technologies and commercialize products in pursuit of design features and the ultimate enjoyment of driving while also satisfying high levels of environmental and safety considerations.

We participate in international races such as the Dakar Rally and the Baja 1000, which are said to be the toughest off-road races in the world. The knowledge and experience we gain from these races have fueled our product development, resulting in superior basic performance and aggressive pattern designs. Our efforts have been well received especially in the North American market, where heavy-duty SUVs have been gaining ground.

The spread of EVs is expected to both accelerate and further diversify as it makes its way to the North American market in the future. We will capture the EV market trends and work on our unique strategy to develop and enhance differentiated products that make the most of our strengths.

[TOPIC] Three of our tire products win the Good Design Award 2022

Three of our tires have simultaneously won the Good Design Award 2022 from the Japan Institute of Design Promotion. The OPEN COUNTRY A/T III all-terrain tire for SUVs, TRANPATH mp7 tire for minivans and M937 studless tire for community buses are all designed with distinctive tread patterns that play key functional roles in running vehicles. Our original pattern design technology was acclaimed for unerringly identifying changes in tire use and needs and embodying our approach to product development. Going forward, we will continue to develop products with high added value while pursuing needed advances in tire performance.

Action for Sustainability

- Message from the President

- TOYO TIRE Value creation

- TOYO TIRE Sustainability

- TOYO TIREʼs SDGs

-

TOYO TIRE Materiality

- Help create a society of sustainable mobility / Support the enjoyment of mobility for all

- Support diverse talent with motivating challenges and job satisfaction

- Continue innovating next-generation mobility technology

- Pursue decarbonization in all corporate activities

- Promote supply chain sustainability

- Ensure the fundamentals of manufacturing: quality and safety

-

Sustainability and ESG themes beyond the material issues

- E: Environment

- S: Upholding human rights

- S: Managing occupational health and safety to global standards

- S: Crisis management (responding resiliently to natural disasters, infections and other crises)

- S: Working with local communities (Helping solve local issues)

- G: Sound governance

- G: Compliance

- G: Risk management

- G: Information security

- G: Promoting digital transformation (borderless and centralized business management through ERP reform)

- Toyo Tire Group Charter of Corporate Behavior

- Toyo Tire Group Code of Conduct

- Site Report

- Report Library

- Editorial Policy

- GRI Content Index

- ESG Data/Survey Index

- Communication on Progress (CoP) Index

- External Recognition