Challenges

- Improving product quality

- Increasing customer satisfaction

- Visualizing manufacturing quality using MES

- Creating an RFID system to ensure traceability

- Promoting improved awareness of tire safety

Relevant stakeholders

Direct: Customers (consumers), suppliers, employees, research bodies

Indirect: Shareholders and investors, creditors, local communities, NGOs, industry groups

Our policy

Our principle for manufacturing is to provide high-quality and safe products and services that are useful to society, and our fundamental philosophy and action guidelines for product safety are set forth in the Toyo Tire Group Global Product Safety Policy. The policy details our commitment to focusing on product safety and environmental protection in every step of the value chain, from product planning, development and design to production, sales, use and end of product life.

We operate a product quality management system based on IATF 16949 (or ISO 9001 at some production bases) to take measures against risk.

Global Product Safety Policy

1. Fundamental Philosophy

As a responsible global company, we will promote sustainable management through our corporate activities to further enhance economic, environmental and social value.

We continue to strive and contribute to the creation of sustainable society as global environment protection first, which is put not only safe but also human health harmless.

2. Code of Conduct

- 1. As a company aiming for sustainable growth by creating a better symbiotic relationship between people and the earth, we provide environmentally friendly, safe and reliable products and services to our customers and society.

- 2. To assure the safety of products, we comply with the necessary internal and external rules, laws, regulations, standards and guidelines. We aim to develop products with a higher level of safety and lower environmental impact.

- 3. We consider product safety and global environment protection from the stages of product planning, development and design, through to production, sales, use, and even after the end of use.

- 4. We aim to manufacture without the production loss from the product planning, development, and design stages.

- 5. We consider recycling in the product planning, development, and design stages.

- 6. We conduct education and awareness-raising concerning every employee layer regarding product safety and environmental protection.

- 7. We well-inform and educate customers about methods of suitable use for products and misuse prevention. And we listen earnestly to their opinions and desires, and reflect them in our products. Thus, we will provide the safe and health-friendly products, and promote the global environmental protection.

Quality management system status

ISO 9001 certification (as of the end of May 2025)

Production facilities: 13 sites (3 Toyo Tire Corporation sites*1, 10 affiliated company sites)

Sales bases (affiliated companies): 1 site

- *1 The Kuwana Plant has independently acquired certification at two sites: its tire production plant and automobile parts plant.

IATF 16949 (formerly ISO/TS 16949) certification (as of the end of March 2025)

Production facilities: 9 sites (3 Toyo Tire Corporation sites, 6 affiliated company sites)

Responsible executives (as of April 2025)

- R&D: Director, Corporate Officer and Vice President of R&D Headquarters

- Production Technology: Corporate Officer and Vice President of Production Headquarters

- Products and services: Director, Corporate Officer and Vice President of Sales Headquarters

- Quality assurance: Senior Corporate Officer and Vice President of Quality Assurance, Environment & Safety Headquarters

Organizational responsibilities (as of April 2025)

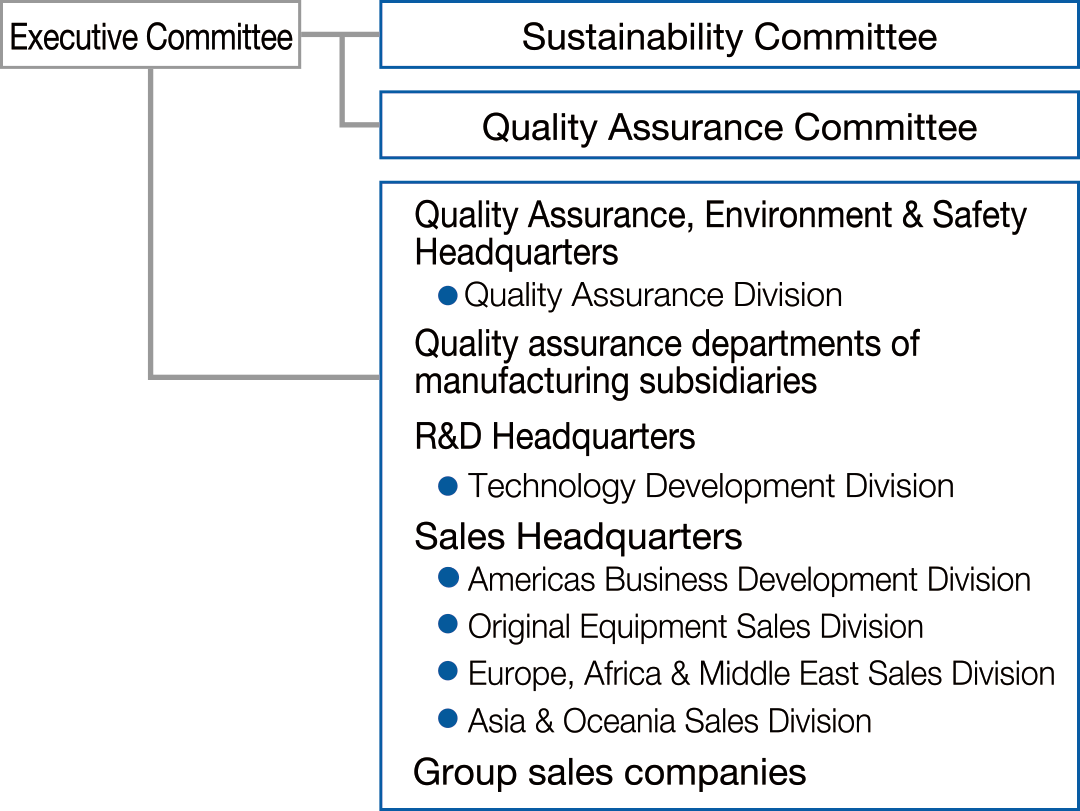

Quality Assurance, Environment & Safety Headquarters is responsible for promoting initiatives in this area, and reports progress to the Sustainability Committee.

Reporting systems

- Reporting hotline (whistle-blowing system): For executives, employees and suppliers

- Customer Relations Department: For customers (consumers) and local communities

- Online inquiry form: For customers (consumers), shareholders and investors, and NGOs

In addition to the above routes, our technical service departments, Group sales companies and distributors also receive inquiries and complaints.

Improving product quality

Improving the development & production process

In manufacturing, we believe it important to achieve greater quality in upstream business processes. We aim to not only raise the quality of the products and services we introduce to the market, but also that of the development and production process itself.

For our Group’s newly developed products, the Quality Assurance Division checks the design reviews that are performed at each step, from product planning to the production preparation stage, to ensure that reliable quality is designed in from the start.

At our Tire Technical Center, we are implementing robotic process automation (RPA) software that automatically processes routine tasks. Through this, we aim to see how it improves operational efficiency by preventing potential risks in the course of business, such as human errors and fraud.

Meeting the quality standards of each country

We are aiming to strengthen our own quality standards throughout the Group in order to fully comply with the increasingly complex quality-related laws in each country — such as environmental performance and quality legislation promoting vehicle fuel efficiency improvements and reduced CO2 emissions, being rapidly introduced in the face of rising climate change risks. Once per year in each of our tire and automotive parts divisions, we hold Global Quality Management Committee(Global QMC) led by those in charge of quality assurance and other relevant employees at our production sites in and outside of Japan. At these meetings, each site shares updates such as their product quality status and quality improvements in production processes, and discusses new initiatives for process assurance, the ideal form of quality control. These meetings are also opportunities to share information that goes beyond quality improvement activities, including tire regulations in each country, field quality information, and market trends.

The four sites for Group tire testing and evaluation in Japan received ISO/IEC17025 certification (general requirements for the competence of testing and calibration laboratories) for the first time in 2013, and have since been improving test accuracy and confidence to continuously conduct tests that conform to standard requirements.

Participants in the global quality assurance conference

(left: Tire business, right: Automotive parts business)

Participants in the global quality assurance conference(top: Tire business, bottom: Automotive parts business)

Global QMC

ISO/IEC17025 Certificate of Accreditation

Example efforts to meet quality standards

- Collecting information locally

- Making recommendations by participating in industry groups

- Exchanging opinions with regulatory institutions

- Sharing information on the latest legal and regulatory trends

- Giving presentations on legal and regulatory matters

Improving service quality at sales companies

Our tire sales companies are committed to ensuring that our customers – the consumers – can choose our products with confidence, peace of mind and satisfaction by training our staff to a high standard of customer service and improving the skills of our technicians.

For example, Toyo Tire Japan Co., Ltd. and independent distributors in Japan conduct job-specific training to foster talent that possesses the required level of service quality for their respective roles, such as sales and customer service. They also provide specialized training to sales associates and front office staff to equip them with the awareness required to convey product value to customers clearly and correctly on a day-to-day basis, and to develop the skills required for their respective roles.

We also hold a Truck and Bus Tire Servicing Contest to improve the skills and service level of technicians who exchange tires and perform inspections and after service, and to help prevent accidents caused by wheel detachment on large vehicles—a matter of public concern. Technicians selected from all over the country compete to show their skills, and the activity also illustrates how their own jobs help both customers and society, fostering a sense of duty and motivation toward their work.

Truck and Bus Tire Servicing Contest

Truck and Bus Tire Servicing ContestIncreasing customer satisfaction

Maintaining and improving quality and satisfaction

As a manufacturer, we understand that our products and services link us to both customers and society, and we

are working to improve quality throughout the entire value chain. Our production bases are continuously searching for ways to maintain and improve product quality, while our technical service departments continuously investigate product satisfaction levels in the market and relay customer requests as feedback to planning, design and production departments. Our Customer Relations Department analyzes the opinions and inquiries received from customers (consumers) on a day-to-day basis and makes recommendations for improving products and services to relevant departments. All other workplaces also strive to provide services and improve the quality of our operations from a customer perspective. These activities reflect the spirit of our Company Philosophy of continuously improving our products and creating value for everyone we work with.

For example, for more than 50 years, we have held Quality Control (QC) circle activities to proactively raise quality control standards using employee insight from the frontlines. QC circles began at production sites and have now spread to sales divisions, with about 300 total circles currently running within the Group. Members bring with them their experience and knowledge in order to resolve problems, and work to improve quality by understanding current conditions, setting goals, developing activity plans and analyzing issues.

Each year we run a company-wide QC circle event where circle representatives from around the world visit our head office to present local initiatives for improving quality control and eliminating waste and loss in the workplace, with the aim of achieving a global information and learning exchange. Just as in 2023, the 2024 event took place remotely with circle representatives from each base making online presentations that were assessed by a panel of judges. Moving forward, we will continue supporting QC circles to further improve worksite autonomy and customer satisfaction.

Responding to feedback from consumers

Every piece of feedback that we receive from our customers is valuable and provides us with opportunities to understand their expectations for the Group and improve our products and services. In 2024, our Customer Relations Department received a total of 2,616 inquiries in Japan. We respond to phone and online contact from customers both accurately and simply.

We analyze the content of these inquiries and send the findings to relevant departments to improve the usability of our products and services. Such efforts have led to the development of the Open Country series, our popular line of SUV tires, and the improvement of the readability of our catalogues and websites.

We take complaints seriously, and work with the Group's sales divisions and technical service departments to ensure that issues are dealt with promptly and satisfactorily, and that the problem or complaint is resolved so that we can build a long-lasting positive relationship with the customer.

Visualizing manufacturing quality using Manufacturing Execution Systems (MES)

Visualizing manufacturing process quality data to improve processes

The Toyo Tire Group aims to build a quality assurance system that can predict and prevent issues from occurring in the manufacturing process. We have introduced automatic measuring instruments into the tire manufacturing process, and are launching a system that digitally collects and visualizes quality- and production-related information from production equipment. This will ensure quality in each manufacturing process, and make it possible to analyze and monitor collected data to detect changes in process trends.

We have been operating the manufacturing execution system (MES) at our Serbia Factory since 2024. We plan to expand its implementation to quality-related domains and analyze the results to introduce the system at other production bases. At the same time, we are also working to promote wider use of data through human resource development as well as by developing a data-driven corporate culture.

Panoramic view of the Serbia Factory

Panoramic view of the Serbia FactoryCreating an RFID*2 system to ensure traceability

In May 2022, the Global Data Service Organization for Tires and Automotive Components (GDSO) was established as an international non-profit organization working to standardize and share tire data in the industry. We are developing the technology and production facility to equip tires with radio frequency identifier (RFID) tags, and exploring how the data acquired through the technology can be used.

- *2 Creating an RFID system to ensure traceability

Promoting improved awareness of tire safety

As a tire manufacturing and sales company, we at the Toyo Tire Group see it as our duty to educate customers on the importance of regular tire inspections for improving safety. Each year we run tire safety awareness events.

【TOPIC】Tire safety awareness activities in 2024

We believe that it is a duty of our Group as a manufacturer and a company committed to mobility to raise drivers’ awareness of the need for regular tire inspections to ensure their safety. We run campaigns to raise awareness of tire safety, highlighting the need for regular tire inspections, giving tips for driving in rain and promoting other safety-conscious practices.

In order to help drivers to understand the importance of maintaining tires in good condition, we have been running tire safety awareness campaign events across Japan since 2019 using a driving simulator with our proprietary software. In 2024, we worked with Itami City, where we are headquartered, as well as the Japan Automobile Federation (JAF) and nearby police departments to provide this experience to 3,513 people at 72 shopping centers, partner retail outlets and other locations around Japan. In the post-workshop questionnaire, 97% of respondents indicated that their awareness of tire safety has increased.

The driving simulator provides a realistic driving experience by recreating views from the driver’s seat as well as road noise and vibrations, which are all synched to inputs through the steering wheel and the accelerator and brake pedals, so that participants can experience how driving around a corner in rain feels when tires are worn, what the difference in braking distance is between tires with sufficient tread and those with worn tread, and what happens when a tire blowout occurs while driving. By giving drivers opportunities to experience these unfamiliar situations through simulation, we try to make them aware of the importance of keeping tires in optimal conditions.

We will continue using our driving simulator to further boost interest in tires and help make drivers aware of how to use them properly.

Tire safety awareness campaign events