Challenges

- Developing products, materials and technology for a society of next-generation mobility

- Expanding the use of sustainable raw materials

- Efforts to reduce TRWP

- Supporting safe driving (improving safety awareness through data)

- Enforcing intellectual property strategy

Relevant stakeholders

- Direct: Customers (consumers), suppliers, employees, research bodies

- Indirect: Shareholders and investors, creditors, local communities, NGOs, industry groups

Our policy

The Toyo Tire Group believes that the value we provide through our products and services must support the evolution of mobility required for a new age. We will continue to challenge technological innovation to help build a society that exists in harmony with the environment and supports safe driving.

Our goal

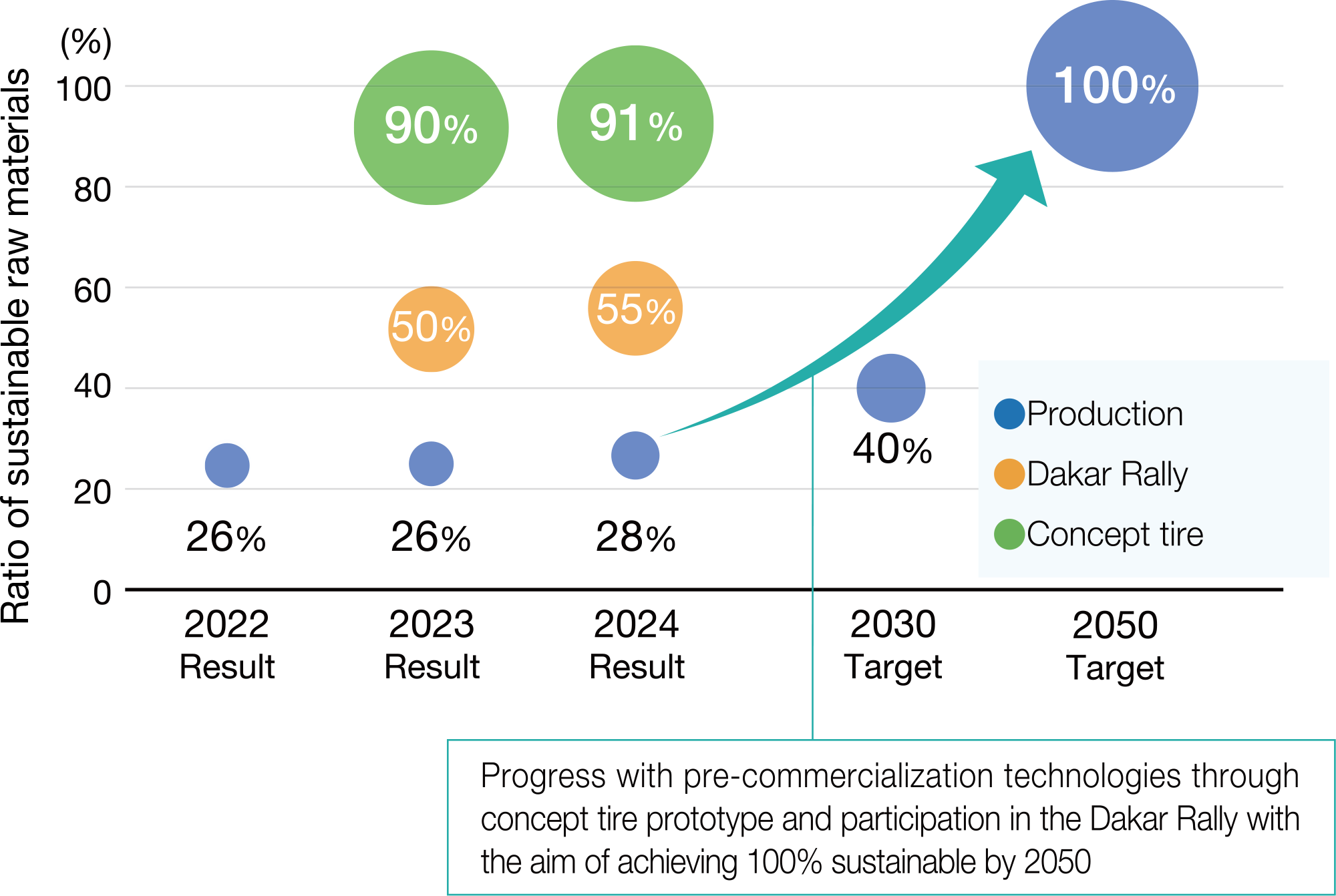

Our goal is to increase the ratio of sustainable materials*1 to 40% by 2030 and 100% by 2050.

- *1 Sustainable materials are defined by Toyo Tire as recycled and renewable raw materials.

Responsible executive (as of April 2025)

Director, Corporate Officer and Vice President of R&D Headquarters

Organizational responsibilities (as of April 2025)

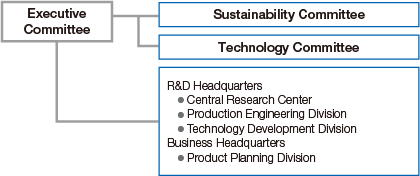

R&D Headquarters is responsible for promoting initiatives in this area. The Technical Committee oversees all initiatives and reports progress to the Sustainability Committee.

Reporting systems

- Reporting hotline (whistle-blowing system): For executives, employees and suppliers

- Customer Relations Department: For customers (consumers) and local communities

- Online inquiry form: For customers (consumers), shareholders and investors, and NGOs

Discovery Channel × TOYO TIRES Technology

Expanding the use of sustainable raw materials

We believe it is our mission as a manufacturing company to help promote the transition from a society that consumes resources to a society that circulates resources. We conduct research and development with the aim of increasing the ratio of sustainable raw materials*2 used in our products to 40% by 2030, and 100% by 2050. That ratio reached 28% at the end of 2024.

Going forward, we will continue developing technologies to increase the use of recycled raw materials such as reclaimed rubber made from used tires, recovered carbon black (rCB) and recycled bead wire, as well as renewable raw materials such as synthetic rubber made from biomass (biomass-derived butadiene rubber and biomass-derived styrene butadiene rubber) and rice husk ash silica.

This would lead to a reduction in the amount of petroleum-derived raw materials used, which have a large impact on climate change, and help reduce GHG emissions over the tire lifecycle.

- *2 Toyo Tire Corporation defines sustainable raw materials as recycled raw materials and renewable raw materials.

| Recycled raw materials | Renewable raw materials | |

|---|---|---|

| Main sustainable raw materials |

rCB | Biomass-derived synthetic rubber |

| Recycled steel cord | Plant-derived oil | |

| Recycled bead wire | Rice husk ash silica |

Ratio of sustainable raw materials: targets and actual results

【TOPICS】

1. Developing concept tires made from 91% sustainable raw materials

In January 2024, we announced a tire made from 90% sustainable raw materials at the Tokyo Auto Salon 2024. We then increased that ratio by a further one percent with a prototype tire boasting the industry’ highest ratio of sustainable raw materials at 91% (source: Toyo Tire Corporation), which we showcased at the Tokyo Auto Salon 2025. The sustainable materials include 62% renewable raw materials and 29% recycled raw materials. The prototype was produced to the actual driving strength and quality of OPEN COUNTRY R/T, and we were also able to confirm its sustainable qualities even for off-road specifications.

Going forward, we will continue to perfect this tire’s technological innovation and press for early commercialization as a product that can help realize an era of sustainable mobility.

Concept tires made from 91% sustainable raw materials

2. Commencing joint research on sustainable raw materials with the University of Novi Sad, Republic of Serbia

Toyo Tire Holdings of Europe GmbH, our holding company in Europe, has concluded an industry-university partnership agreement with the University of Novi Sad in Serbia for the research and development of sustainable raw materials in November 2023.

The partnership started out with two joint research themes as part of our drive to expand the use of sustainable raw materials. The first theme focuses on the development of renewable raw materials using plants sourced from Serbia, and we are currently expanding our search for potential Serbian plant candidates. The second theme focuses on developing recycled raw materials from waste tires, and we are currently developing rubber recycling technology with an emphasis on efficiency. Going forward, we will continue to actively utilize open innovation to help realize a sustainable society.

■Details of joint research

Initiatives to facilitate the use of sustainable raw materials

1. Development of renewable raw materials utilizing plants grown in Serbia

2. Development of recycled raw materials derived from waste tires

3. Successful synthesis of butadiene rubber from CO2 for the development of tires made from sustainable raw materials

In May 2023, we announced that joint research conducted with the University of Toyama has resulted in the development of a catalyst that converts carbon dioxide into butadiene at a high yield rate, and the successful synthesis of butadiene rubber, which is one of the main raw materials for tires. Carbon dioxide is considered to be one of the main drivers of climate change that causes serious adverse impacts on the global environment. Our success in pioneering the natural synthesis of butadiene from carbon dioxide will help minimize our environmental impact (in terms of carbon dioxide emissions) during the production process, compared to existing petroleum-derived raw materials. Having enlisted the help of external partners, we have been considering mass production, while also researching and developing the potential replacement of other raw materials with sustainable alternatives.

4. Acquiring ISCC PLUS certification*3

In December 2024, we acquired ISCC PLUS certification, an International Sustainability and Carbon Certification framework for sustainable products, at our main Sendai Plant (Iwanuma City, Miyagi Prefecture) production base in Japan and at our Fukushima Rubber Co., Ltd. production subsidiary (Fukushima City, Fukushima Prefecture). The two successful certified plants will be able to handle certified raw materials in compliance with the mass balance approach.*4 We remain committed to systematically promoting the use of certified products and other sustainable raw materials.

- *3 An independent certification system designed to ensure the proper management of biomass raw materials and products as well as recycled raw materials and products in the supply chain.

- *4 An accounting method used when products contain a mixture of raw materials with differing characteristics. It enables a certain percentage of any manufactured products to be assigned a characteristic (e.g., certification as recycled) according to the input volume of raw materials with that characteristic.

5. Developing the Tire SAPRI digital application for managing the condition of truck and bus tires

We have developed the Tire SAPRI digital application that helps grasp and manage truck and bus tire usage environments and status, and have already started test marketing the app to select customers. We are seeking to use our unique digital data processing technologies, such as displays of predicted tire wear as well as abnormality notifications based on tire pressure and temperature monitoring, to create new value through solutions that can, for example, ensure efficient management of vehicle operations and prevent operational problems for logistics companies.

Efforts to reduce TRWP

Tire and road wear particles (TRWP) are dust produced by friction between the tire and the road surface that is a mixture of tire tread and road paving materials. Since the dust is discharged into the atmosphere, tire manufacturers view the need to reduce TRWP as a key issue. Any wear on tires does impact safety, comfort and fuel efficiency, so we are always striving to improve wear resistance through materials development and improved tread design.

We also actively participate in industry groups, the Tire Industry Project (TIP)*5 and JATMA, to conduct research and study ways to mitigate the impact of TRWP since there are still many things about TRWP that have yet to be determined. We will continue to contribute to the industry’s efforts in this area, while also using any knowledge we acquire though these industry-wide activities to improve our own initiatives on reducing TRWP.

Furthermore, TRWP includes 6PPD*6, an anti-degradant that is widely used in the global tire industry. A paper published in the United States indicates that 6PPD-quinone, a transformation product that can form when 6PPD reacts with oxygen or ozone, impacts certain types of fish. As a member of the tire industry, we are also conducting various research and assessing alternative products.

- *5 One of the sector projects of the World Business Council for Sustainable Development (WBCSD)

- *6 N-(1,3-dimethylbutyl)-N’-phenyl-p-phenylenediamine. An anti-degradant additive used to prevent the tire surface from cracking and degrading

Supporting safe driving (providing data to ensure driver safety)

Tires are the only components of a vehicle that actually come into contact with the road surface, and we are developing sensing technology that can collect various types of information from tires. The concept we are working to take forward is to create new added value by turning tires into data acquisition devices. Using this technology, we developed a software application that processes data inputs from sensors attached to tires to derive the limits of the required tire performance, uses them to determine whether the tire force*7 of the running tires is within the performance range required for the road conditions, and provides real-time display. We are currently working to improve sensing accuracy by taking measurements of road surfaces under a range of conditions and proving the concept by testing the application on driving tracks. We will continue developing these technologies to serve as a part of safety systems required for autonomous driving.

- *7 Tire force is a term we use to describe the real-life tire performance, as estimated from data inputs from the tire such as air pressure, temperature, identified road surface condition, load, wear, and any anomalies detected.

Taking road surface measurements using mounted sensors

Activities: Intellectual property strategy

We pursue technological innovation and product development designed to realize an environmentally friendly society and an era of safe mobility. However, we believe that the new technologies and products we create through these initiatives only truly acquire social value when they are delivered into the hands of our customers and put to use. We acquire the intellectual property rights that underpin the technical support required to enable the safe use of the products that result from our research and development into recycled raw materials, renewable raw materials, fuel-efficient rubber compounds and other areas. We believe that these ongoing intellectual property initiatives will help create value for the future era of mobility, and also secure our own presence in that arena.

【TOPIC】The 14th company-wide technology development presentation awards

In 2023, the presentation was held online and assessed entries based on the five perspectives of originality, rationality, future potential, development speed, and presentation. This initiative will be continued in the future as we further our technological developments to continue responding to the needs of society.

2024 Awarded Topics

Outstanding Technological Development Award

Toughening rubber with a new crosslinking agent

With sustainability goals in mind, Toyo Tire Corporation is promoting the development of technologies that toughen rubber materials in an attempt to reduce CO2 emissions and effectively use resources by extending the lifespan and reducing the weight of tire products. Employing nanoscale structural analysis technology built with Nano Balance Technology, which is our fundamental material design technology, we discovered that, based on the relationship between rubber properties and hierarchical structures, the uniformity of crosslinking structures can greatly enhance the toughness of the material, and we successfully developed a new crosslinking agent that can control this process.

Unique Award

Developing a no-changeover band transfer

We have to provide the market with various tires sizes to meet customer needs. To effectively utilize our production equipment and produce tires of various sizes, we have to alter the status of the production equipment to suit the specific tire size (changeover). That can increase the burden on workers and result in lost production time when equipment is idle. We have developed a new method that enables various tire sizes to be produced without changing over equipment settings for the band transfer part, which would normally require a changeover. We believe this development will help alleviate worker task load and provide more tires to the market.

Surprise Award

Using MI to promote the adoption of new raw materials and new compounds and the timely improvement of tire performance

Competition among leading global manufacturers is driving more advanced tire performance and shorter development cycles, and the use of AI technology in product design is also expanding. Toyo Tire Corporation has been using materials informatics (MI) to create more sophisticated compound designs for some time and we have recently started using MI in the design of raw material polymers. Tread compounds using the polymers and formulation methods recommended by this new initiative are being used primarily in new products for North America. They maintain the low temperature and wear resistance levels required by the North American market, while also delivering significantly improved performance on wet surfaces.