Challenges

- Addressing nature-related risks and opportunities (TNFD)

- Addressing water resources

- Addressing WASH issues

- Addressing biodiversity

- Contributing to the circular economy

- Reducing waste

- Preventing chemical pollution

Relevant stakeholders

Direct: Local communities, the environment, customers

Indirect: Shareholders and investors, creditors, NGOs/NPOs, industry groups

Our policy

Our Global Environmental Policy commits us to supporting international standards, and we adopt a precautionary approach in our efforts to help solve global climate change and other environmental challenges across the value chain.

We take early action to address environmental issues through this precautionary approach such as risk assessments to support international norms, including the United Nations (UN) Rio Declaration on Environment and Development and Agenda 21 and 10 principles of the UN Global Compact, and fulfil our responsibilities. Following the release of the final recommendations (ver. 1.0) of the Taskforce on Nature-related Financial Disclosure(TNFD) in September 2023, we started initial disclosures where practicable.

Global Environmental Policy

1.Fundamental Philosophy

The Toyo Tire Group aims to create a sustainable society, where we share all-encompassing affluence and joy with everyone involved in our business. To this end, we hereby pledge to fulfill our corporate responsibility to the global environment into the future, as we seek to achieve TOYO TIRE's SDGs for resolving social issues on a global scale.

2.Action Guidelines

1) We comply with international rules and laws.

We will continue to support international rules for the protection of the global environment and work to comply with environment-related laws and regulations in the countries/regions where we operate.

2) We act to mitigate the impact of the climate crisis.

Climate change is causing various critical situations (climate crises) across the planet. We acknowledge that, for us to stay in business, it is of great importance to respond to this change and whatever changes the future may bring. While contributing to the achievement of internationally-committed goals, such as curbs on energy usage and reduction in CO2 emissions, we will lay a foundation for our business continuity that minimizes the impact on our business in the wake of natural disasters.

3) We use water with the utmost care.

We are cognizant of the importance of ensuring access to safe water (fresh water) at our premises and their surrounding areas for business continuity. Accordingly, we will not only strive to reduce our water consumption but also minimize the impact that the intake and discharge of water that we utilize for our business activities may have on the areas surrounding our premises, with the aim of creating a social environment where it is perfectly safe to use water resources.

4) We do not waste resources.

We are also cognizant of how important it is, for the sake of business continuity, to use only the necessary amount of resources, conforming to a predetermined plan, on the premise that all resources on this planet are limited. We will also contribute to the development of an enriched social structure for utilizing resources with enhanced efficiency by using precious resources effectively and without waste.

5) We continue manufacturing with considerations given to the environment and people’s lives.

In each process of the value chain, we determine if precautions are taken to conserve the environment and ensure that chemical substances are used safely. We will adhere to these measures to continue to provide products, technologies, and services that enrich the environment and the lives of people.

6) We protect the rich natural environment and people's lifestyles in places where we source our raw materials.

Being fully aware of the fact that we consume large quantities of natural rubber as raw materials for our products, we will strive to protect bountiful forests in places of its origin, as well as the lifestyles of people living there in collaboration with all involved organizations.

7) We value communications with the public

We are cognizant of the importance that, as a corporate citizen of society, we act with a full understanding of the enduring impact that our business activities may have. Therefore, we will strive to facilitate communications and build a better relationship with the public through a series of constructive and sound dialogues with them in order to ensure that we understand ourselves better and that the public develops an unobstructed understanding of our company.

3.Maintaining/Improving Management Systems

Officers and organizations in charge of safety & environment shall be held responsible for the content of this Charter and promote business activities in line with it throughout the Toyo Tire Group.

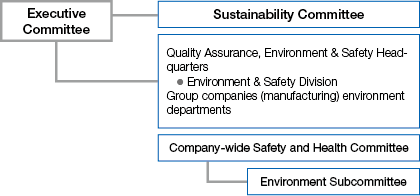

The departments in charge of implementation shall determine their action plans (targets) in accordance with the action guidelines and strive to realize the basic principles laid out in this Charter. The Environment Subcommittee of the Companywide Safety and Health Committee audits the content of the action plans and their progress annually to evaluate the outcome of such actions and, if deemed necessary, provide guidance on improvement.

Plans (targets) and their progress for matters of particular importance in the action guidelines, such as climate change, water, and resources, shall be reported periodically to the Board of Directors.

Environment Subcommittee FY2025 priority measures

| Measures being developed | Targets |

|---|---|

| Promote the proper disposal of industrial waste |

|

| Confirm environmental issues at all sites and promote corrective measures |

Conduct audits, identify issues, and confirm corrections have been made

|

| Improve the accuracy of environmental data for disclosure |

Improve accuracy to reduce the identification of deficiencies in environmental data (energy, water, waste) during third-party verifications to zero |

| Ensure that the impact of water withdrawal and discharge on the surrounding environment is considered in the activities of all sites |

|

| Ensure thorough management of hazardous chemical substances at our sites in Japan |

|

Operational status of environmental management system

ISO 14001 certification at manufacturing sites (as of December 31, 2024)

Number of manufacturing sites (globally): 11

ISO-certified sites: 10 (certification rate: 90.9%)

<Reference>

ISO 14001 certification at manufacturing sites (as of January 31, 2024)

Number of manufacturing sites (globally): 11

ISO-certified sites: 10 (certification rate: 90.9%)

Responsible executive (as of April 2025)

Senior Corporate Officer and Vice President of the Quality Assurance, Environment & Safety Headquarters

Organizational responsibilities (as of April 2025)

- *Toyo Tire Corporation

Reporting systems

- Reporting hotline (whistle-blowing system): For executives, employees, suppliers

- Customer Relations Department: For customers (consumers) and local communities

- Online inquiry form: For customers (consumers), shareholders and investors, and NGOs/NPOs

Main resources for promoting activities (2024)

- Expenses for preventing pollution of air and water systems: 134 million yen

- Expenses for recycling resources: 744 million yen

- Expenses for managing environmental activities: 81million yen

- * Adheres to the Environmental Accounting Guidelines 2005 (Japan’s Ministry of the Environment). Includes depreciation of depreciable assets.

- * Main business area: Japan

Environmental accounting

Addressing nature-related risks and opportunities (TNFD)

In 2023, the Taskforce on Nature-related Financial Disclosures (TNFD) published version 1.0 of its recommendations and the Science Based Targets Network (SBTN) published version 1.0 of its guidance for setting Science Based Targets for Nature (SBTs for Nature), which clearly set out the role that companies must play for nature: avoid and reduce the impact of their business activities, and regenerate and restore ecosystems.

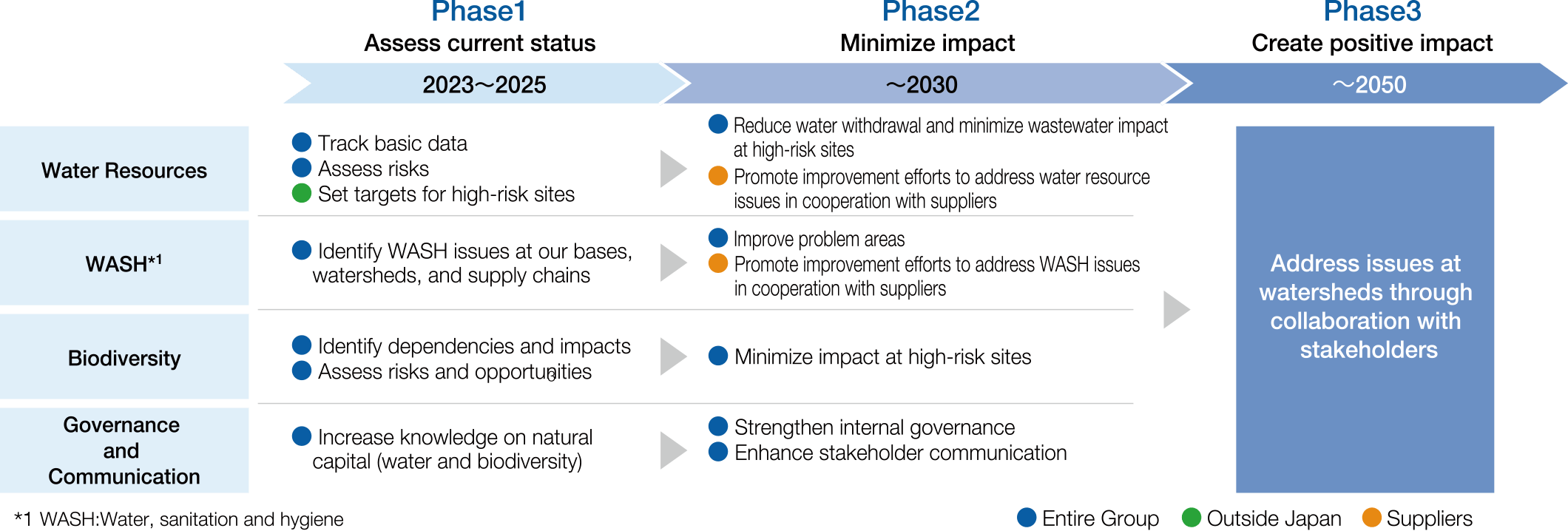

We recognize that our operations depend on natural capital including natural rubber and water resources, and that we as a company have a significant impact on nature. In 2023, we established a long-term roadmap that guides our operations onto a sustainable footing by assessing the current status of the locations where we operate, minimizing our negative impact on nature, and creating a positive impact.

Long-term roadmap

In 2023, we developed a long-term roadmap that recognizes the natural capital we rely on, which includes not only water resources but also sanitation and hygiene (WASH) and biodiversity.

We are currently engaged in activities with the aim of completing phase 1 (assess current status) in 2025. In 2024, we started assessing the current status of WASH issues and biodiversity while continuing the work to address water resource issues that started in 2023.

Addressing water resources

Addressing water-related risks and opportunities

In 2023, following the Aqueduct assessment that found our Chinese operations to be high risk for water depletion, we set a target of reducing water withdrawal intensity at our bases in China by 10% by 2030 compared to the 2023 levels.

By continuing the program of facility improvements to maximize the recycling and reuse of water used in production processes as well as implementing water withdrawal management with a focus on raising awareness of the importance of natural capital through measures such as section-level target-setting, we have reduced water withdrawals per unit of production from 7.7 (m3/t) to 7.1 (m3/t) in 2024. This represents 8.0% of the 10% reduction target for 2030.

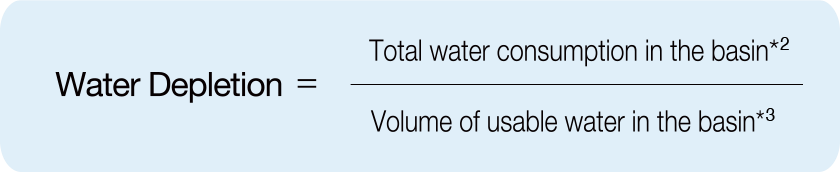

- *2 Water consumption: The amount of water withdrawn that cannot be reused

- *3 Volume of usable water = Volume of water resources in the basin – Volume of water consumption from the basin

- ・Assessment indicators: Of the two Aqueduct water resource risk assessment indicators, Water Stress and Water Depletion, Toyo Tire Corporation uses Water Depletion to conduct its risk assessments because that is a more pertinent representation of the water resource situation in the basin.

- ・Assessed areas: 12 areas where the Group has manufacturing bases

- ・Assessment period: April 2023

- ・Assessment results: One high risk area in China (Zhucheng City). One medium-high risk area in Thailand. All the other areas were low risk.

Reducing volume of water withdrawal and managing discharge appropriately

Recognizing the importance of the conservation and efficient use of water resources, the Group has defined targets for reducing water use and is implementing measures to promote water saving and expand the use of recycled wastewater across the Group.

The Group mainly uses municipal or other public and private water supply facilities as well as groundwater for our boiler equipment and parts processing facilities, the cooling of production parts, cooling towers and welfare facilities at our manufacturing bases. For water withdrawal and discharge, we are working on proper water-resource management throughout the Group using efforts such as improving equipment to reuse water as much as possible in each production process. At our main bases in Japan and abroad, except those categorized as high risk, we track changes in water withdrawals per unit of production in order to manage and maintain appropriate levels of water use.

Water withdrawal

Click here to view the data for 2020-2024.Water discharge

Click here to view the data for 2020-2024.Management of water discharge-related impacts at our manufacturing sites

Click here to view the data for 2020-2024.Third-party assurance:

To ensure the accuracy and reliability of the data that we disclose, we have obtained the assurance of a third-party organization for our 2024 environmental data.

- Verification scope: 114 sites* belonging to Toyo Tire Corporation and related companies, for total scope 1 energy-derived CO2 emissions, total Scope 1 energy-derived CH4 and N2O emissions, total Scope 2 emissions, Scope 3 Category 1, 11 and 12 emissions, total water withdrawal, breakdown of water withdrawal, total water discharge, and breakdown of water discharge

- *Toyo Tire Corporation (Headquarters, Sendai Plant, Kuwana Plant (tire and automotive parts), Hyogo Manufacturing Complex, Corporate Technology Center, Tire Technical Center, Automotive Parts Technical Center, Miyazaki Tire Proving Ground, Saroma Tire Proving Ground, Tokyo Office, Hiroshima Office, Kanto Distribution Center, Kansai Distribution Center); Fukushima Rubber Co., Ltd.; Ayabe Toyo Rubber Co., Ltd.; Orient Machinery Co., Ltd. (Headquarters, Sendai branch, Rokko branch); Toyo Tire Japan Co., Ltd. (88 sites); Toyo Tire North America Manufacturing Inc.; Toyo Automotive Parts (Guangzhou) Co., Ltd.; Toyo Tire (Zhangjiagang) Co., Ltd.; Toyo Tire (Zhucheng) Co., Ltd.; Toyo Tyre Malaysia Sdn. Bhd.; Toyo Rubber Chemical Products (Thailand) Limited; Toyo Tire Serbia D.O.O.

- Verification period: January 2024 to December 2024

- Verification criteria: ISO14064-3: 2006, related laws and regulations, and the assurance organization’s protocol

- Third-party assurance organization: SGS Japan Inc.

Water consumption

Click here to view the data for 2020-2024.

In fiscal 2024, there were no legal violations related to water quality, water withdrawal or water discharge.

Addressing WASH issues

There are wide-ranging factors contributing to WASH issues from water resource scarcity and water pollution to a lack of sanitation facilities. In order to gain a clear understanding of the WASH challenges faced in our bases, their watershed areas and supply chains, we have started gathering and sorting information on WASH in the locations associated with our operations. The insights gained through this exercise will be used to implement improvements where WASH issues are present, with an approach that seeks harmonious coexistence with local communities that live on the natural capital we draw from.

Understanding access to safe drinking water and sanitation (drainage and sewage management)

We have looked into the ratio of the population that has access to drinking water and sanitation facilities that meet a certain service level*4 in countries where our production bases are located. Our findings show that a relatively small proportion of the population has access to drinking water in China and Thailand and to sanitation facilities in Serbia and Thailand.

- *4 Monitoring data from the WHO/UNICEF Joint Monitoring Programme for Water Supply, Sanitation and Hygiene (JMP) was referenced and service levels assessed using the WHO/UNICEF recommended methodology based on factors such as the condition of facilities, treatment process and access time.

| Country | Population with access to drinking water (%) |

|---|---|

| Japan | 90-100 |

| China | 40-50 |

| Malaysia | 90-100 |

| Thai | 40-50 |

| America | 90-100 |

| Serbia | 80-90 |

| Country | Population with access to sanitation facilities (%) |

|---|---|

| Japan | 90-100 |

| China | 80-90 |

| Malaysia | 90-100 |

| Thai | 60-70 |

| America | 90-100 |

| Serbia | 60-70 |

Going forward, we will conduct studies focusing on the local areas of our production bases and review what WASH issues to be addressed, including the expected future trends. Where we find significant WASH-related problems, we plan to develop and implement a program of improvement.

Addressing biodiversity

Guided by the approach recommended by the TNFD, we have started assessing the dependency and impact of the business activities of our production bases and supply chains on natural capital including biodiversity, as well as the state of natural capital where our activities are located.

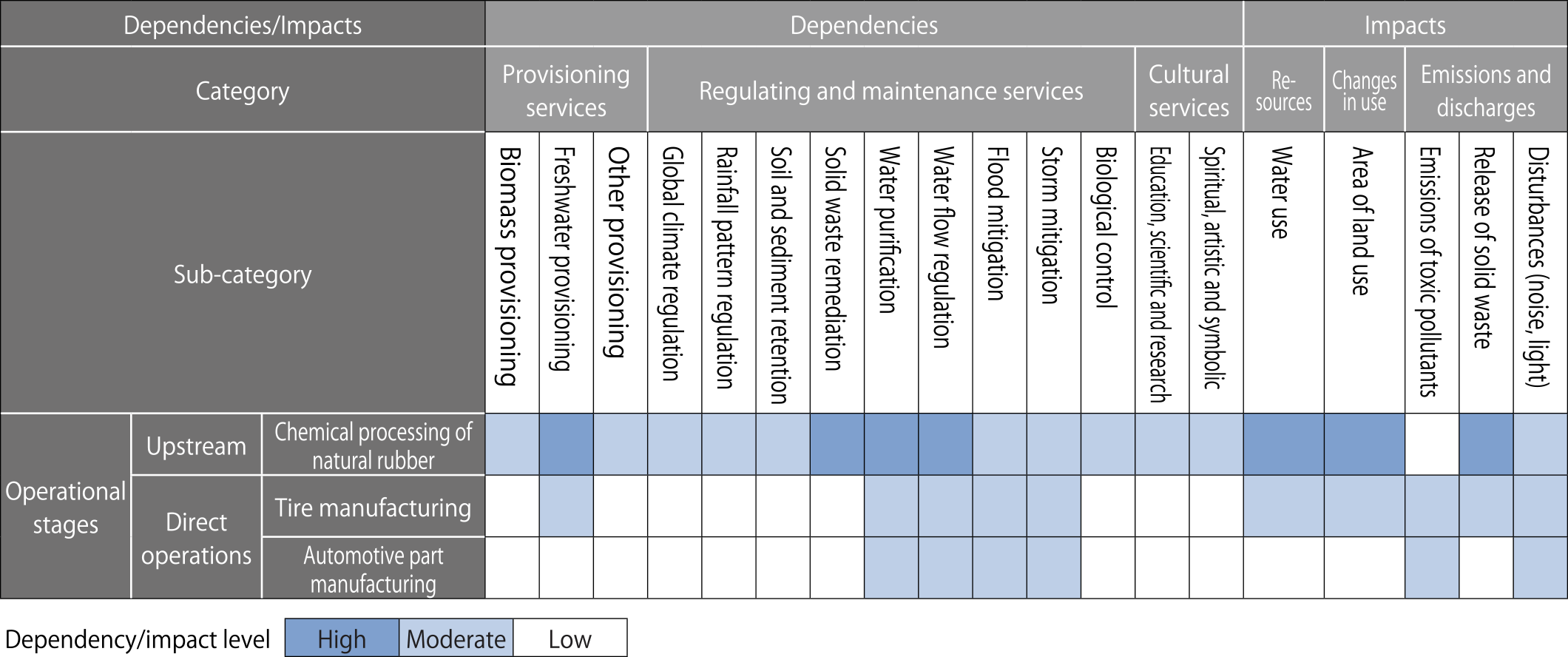

Dependency and impact of the activities of our production bases and supply chains on natural capital

Using the tool recommended by the TNFD for assessing dependencies and impacts on natural capital (ENCORE*5), we have conducted assessments of the dependencies and impacts of our business activities based on the actual processes they involve and identified areas of relatively high dependency and impact as shown in the table below. This exercise has revealed that the Company’s manufacturing activities and the chemical processing of natural rubber in the upstream rely heavily on nature’s services to supply purified freshwater, and that their water and land use, as well as their waste discharge and disturbances (such as noise and light), impact nature significantly.

- *5 A tool that helps users to examine their exposure to nature-related risks and understand their dependencies and impacts on nature.

State of natural capital where our manufacturing operations are located

We are conducting assessments of the state of nature in the local areas around our production bases and processing plants for the relatively high dependency/impact categories identified above. Some of the assessment results for tire production are shown in the heatmap below, which shows the level of dependency/impact of each tire production base on different ecosystem services.

| Production base (tire manufacturing) |

Dependencies | Impacts | ||||||

|---|---|---|---|---|---|---|---|---|

| Water provisioning | Water purification | Maintenance of healthy water cycle | Water use | Emission of air pollutants | Emission of toxic pollutants to water and soil | Release of solid waste | Disturbances (e.g., noise, light) | |

| Japan(Sendai) | ||||||||

| Japan(Kuwana) | ||||||||

| Japan(Fukushima) | ||||||||

| North America | ||||||||

| China | ||||||||

| Malaysia | ||||||||

| Serbia | ||||||||

- Assessment tools: WWF Biodiversity Risk Filter, WWF Water Risk Filter, Aqueduct, and Integral Biodiversity Assessment Tool

We will continue expanding the scope of our studies while conducting assessments of ecologically sensitive areas in order to identify priority areas for improvements and appropriate measures to implement. We will also ensure that timely disclosures are made to our stakeholders.

Contributing to the circular economy

Resource recycling

We believe it is the social responsibility of global manufacturers to make it their mission to help transition our society from one that consumes resources to one that recycles resources.

The Toyo Tire Group is using an increasing amount of raw materials as the scale of our production expands. We strive to secure a stable and sustainable supply of natural rubber, our prime raw material, and other materials at the procurement stage. At the same time, we are also working hard to promote research and development of new materials and improve product design and production processes to ensure more efficient material use. We are also in the process of evaluating sustainable materials and their usage.

We are also trying to extend the life of our products by manufacturing products with excellent durability during use and turning old tires into retread tires.

Targets

Increase sustainable material*6 content to 40% by 2030 and 100% by 2050.

- *6 Toyo Tire Corporation defines sustainable materials as recycled or renewable materials.

Resource recycling initiatives

- Considering the use of recycled carbon black, recycled steel, recycled bead wire and recycled polyester

- Considering the use of biomass-derived synthetic rubber, plant-based oil, rice husk ash silica

- Promoting the sale of retread tires

Main materials

Click here to view the data on total volumes of raw materials and sustainable material content.High-quality Toyo Tires brand even for retread tires

The collection and recycling of used tires is an important issue for resource recycling in the tire industry. The Toyo Tire Group is striving to expand the use of retread tires as a way to address this issue.

A retread tire is a recycled used tire whose tread rubber (the rubber section that comes into contact with the road surface) has been replaced. With the exception of the tread rubber, the other parts of the tire are reused, which not only saves resources compared to new tires but also reduces CO2 emissions at the production stage.* The energy-saving qualities can be further enhanced by using and managing them in conjunction with fuel-efficient tires. Thanks to these environmental performance features, retread tires are recognized as designated procurement items under Japan’s Green Purchasing Law.

The Group manufactures and supplies durable, high-quality tires, and users also rate our retread tires highly.

The usage history for the base tire of a retread tire is different for each tire. We supply tires that customers can use with peace of mind by building a detailed inspection system that spans the selection through to the pre-shipment of base tires and includes such checks as high-voltage inspections of damage conditions, inspections of the interior of the tires that cannot be detected from the outside, and durability checks of finished products.

We are helping promote resource recycling in the transportation industry by encouraging the spread of high-quality retread tires.

- *Assuming CO2 emissions from the manufacturing of new tires of 100%, CO2 emissions from retread tires are much lower at 64%. (Source: Japan Retreaders’ Association)

Number of retread tires produced (Toyo Tires branded)

Click here to view the number of retread tires produced.How we produce retread tires

There are two ways of retreading tires: (1) a remold method in which tread rubber with no pattern is attached to a base tire, which is then placed in a mold, vulcanized and imprinted with a pattern, and (2) a pre-cure method in which patterned tread rubber is attached to a base tire, which is then vulcanized in a vulcanizer. We use high-grade technology to produce tires using both methods.

Reducing waste

Goal: Maintain 100% recycling rate (achieved end-December 2018)

Unit: Direct recycling volume*/total volume of waste × 100

- * Amount of waste diverted directly to waste disposal operators for recycling (excluding direct landfill volume, in-house incineration volume, and outsourced incineration volume)

Fiscal 2024 result: 100% recycling rate

Click here to view the data on waste volumes.Preventing chemical pollution

For necessary raw materials for continuous operations within the Group, we manage chemical substances in accordance with the laws and regulations of each market in which we operate and our business partner’s guidelines.

For instance, we have strictly managed the use, storage and disposal of specified chemical substances in Japan based on the Chemical Substances Control Law (CSCL). In accordance with the Pollutant Release and Transfer Register (PRTR) system, we assess the amount of targeted chemical substances emitted or moved and register with the relevant authorities. When transferring or providing other organizations with targeted chemical substances, we provide those organizations with a safety data sheet (SDS) in accordance with the SDS system stipulated by the CSCL. We also implement any necessary responses to European Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations, the Global Automotive Declarable Substance List (GADSL), or revisions in business partner’s lists of managed chemical substances.

We are working to maintain a 50% or higher reduction in VOC emissions compared to 2000 levels and continue to reduce them in accordance with the Japan Rubber Manufacturers Association’s voluntary action plan on reducing VOC emissions. The plan covers 17 typical substances used in the rubber industry, with rubber solvents constituting over 60% of the Group’s emissions. We have currently reduced VOC emissions by roughly 80%, far exceeding our goal, but will formulate specific plans for improving manufacturing methods and processes in efforts to reduce emissions even further.

We manage fluorocarbons, which greatly impact ozone layer depletion and global warming, in accordance with Japan’s Fluorocarbon Emission Control Law, and control leakage at less than 1,000 tCO2.

Volumes of PRTR substances handled, released and transferred

Click here to view the data on the volumes of PRTR substances handled, released and transferred.Ozone-depleting substance emissions

Click here to view the data on the emission of ozone-depleting substances.VOC control targets and results

- Control targets: Reduce volatile organic compound (VOC) emissions by 50% from 2000 baseline and continue the efforts

- Applicable operations: Toyo Tire Corporation (Sendai Plant and Kuwana Plant), Fukushima Rubber Co., Ltd. and Ayabe Toyo Rubber Co., Ltd

- Unit of control:VOC emission volumes

- Fiscal 2024 result:80.2% reduction from fiscal 2000 baseline