Creating Disaster Resistant Workplaces

We have enhanced our efforts related to fire prevention management and strengthened our disaster prevention and mitigation efforts taking into consideration our experience with major disasters such as the Great East Japan Earthquake.

Activities such as practical firefighting training and blind earthquake training have been introduced at all business sites, and the goal is for workers to repeatedly participate in these activities to improve their effectiveness and to increase the number of participating employees. We conduct firefighting training for hazardous materials that is NFPA600 compliant, which means they meet the standards set by the National Fire Protection Association (NFPA).

So far, a total of 239 employees have taken a fire safety inspector training course, which began in FY2018, in Japan. As one outcome of such an effort, no fires were reported in FY2020, and the number of small fires was reduced by more than 33% from the previous fiscal year.

Outside of Japan, too, we are taking actions and conducting disaster management drills in accordance with the level of such risks in each country.

FY2020 Emergency Management performance

- Disaster prevention drill implementation record

Japan: 22 sites (Total number 4,196 participants)

US: 1sites (Total number 366 participants)

Oceania/Asia (Excluding Japan): 5 sites (Total number 2,395 participants)

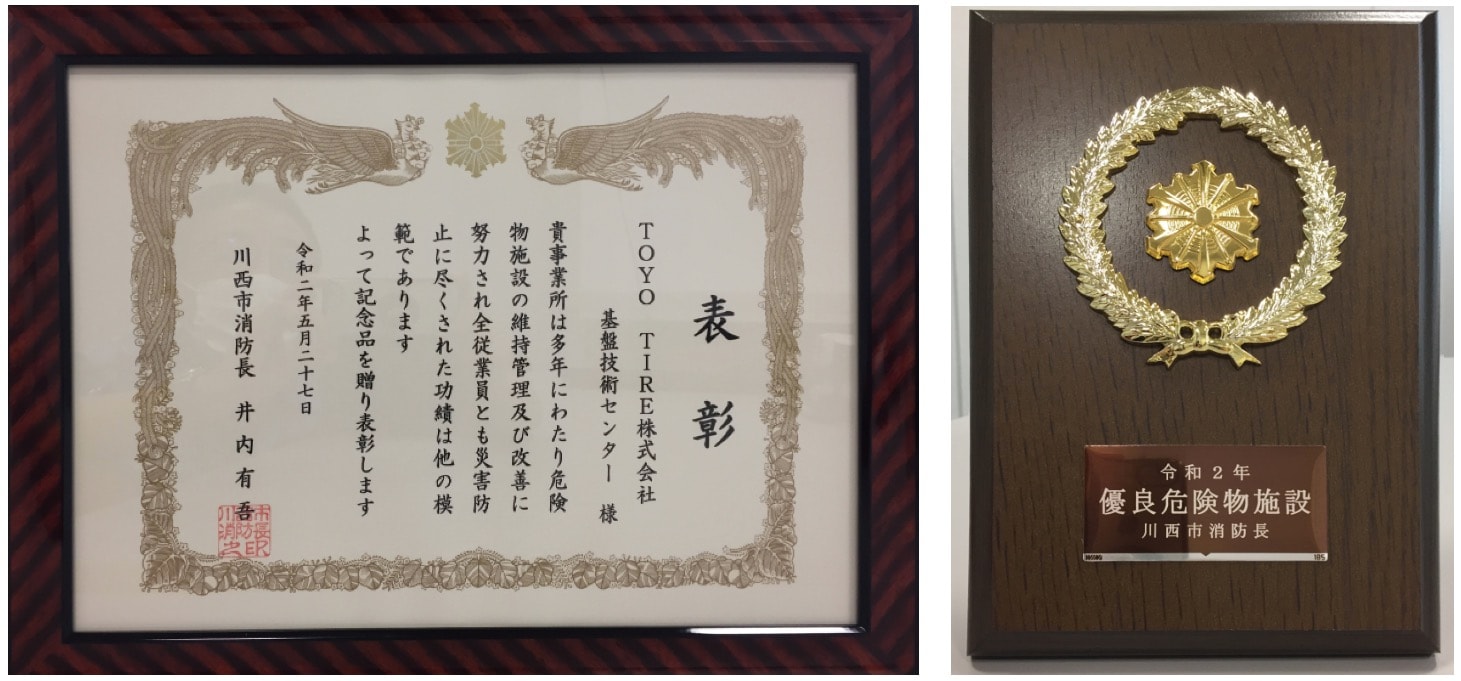

Commended as an Excellent Hazardous Materials Facility by the Kawanishi City Fire Prevention and Safety Association

One of our R&D centers, the Corporate Technology Center (Kawanishi City, Hyogo) is engaged in the maintenance and improvement of the entire premises to prevent accidents when handling hazardous materials. Using the chemical substance management system, they monitor the inventory volume of such materials as well as where they are in real-time to maintain an appropriate management system while encouraging all employees handling hazardous materials to obtain relevant qualifications. In recognition of these initiatives, which are continuously taken throughout the site, in 2020, they were given a commendation by the Kawanishi City Fire Prevention and Safety Association as an excellent hazardous materials facility. We will remain committed to creating accident-free workplace environments through continued efforts.

Sustainability

- Message from the President

- TOYO TIRE Value creation

- TOYO TIRE Sustainability

-

TOYO TIRE Materiality

- Help create a society of sustainable mobility / Support the enjoyment of mobility for all

- Support diverse talent with motivating challenges and job satisfaction

- Continue innovating next-generation mobility technology

- Pursue decarbonization in all corporate activities

- Promote supply chain sustainability

- Ensure the fundamentals of manufacturing: quality and safety

-

ESG Activities

- E: Environment

- S: Upholding human rights

- S: Managing occupational health and safety to global standards

- S: Crisis management (responding resiliently to natural disasters, infections and other crises)

- S: Working with local communities (Helping solve local issues)

- G: Sound governance

- G: Compliance

- G: Risk management

- G: Information security

- G: Promoting digital transformation (borderless and centralized business management through ERP reform)

- External Recognition

- Report Library

- ESG Data

- ESG Data/Survey Index

- GRI Content Index

- Communication on Progress (CoP) Index

- Editorial Policy