Resource Recycling Efforts

TOYO TIRE considers our mission to contribute to the shift from a society that consumes resources to one that recycles as the social responsibility of a manufacturer that conducts business globally.

As the scale of our production activities expands, the amount of raw materials we use also increases. Therefore, we strive to secure a stable and sustainable supply of raw materials indispensable for business growth, such as natural rubber, the main raw material in the procurement stage, in terms of both quality and volume. We are also moving forward with efforts to develop new materials and to improve product design and production processes to make more efficient use of materials. The Toyo Tire Group is making constant efforts to increase material usage efficiency and reduce the amount of final disposal. For example, Toyo Soflan Co., Ltd., for example, reuses 100%* of defective units and discards (cut pieces from the molding process) from its resin product manufacturing process by feeding them back to the process.

As for when products are used, efforts are being made to extend the service lives of products, which includes manufacturing products with outstanding durability and producing reused tires (retreaded tires) from used tires.

All of the Group’s business sites completed risk assessments stipulated by the Industrial Safety and Health Act. In addition to responding to the added chemical substances, we are also introducing reduction risks.

*Excluding products using special materials

Examples of resource recycling efforts

- Moving away from incinerating waste and switching to thermal recycling

- Replaced wooden pallets with more durable plastic pallets

- Examining alternatives for regulated substances

- Efforts related to chemical substance risk assessments based on independent initiatives, wear dust, and used tires

Management of Specific Chemical Substances

Toyo Tire Corporation manages raw materials (chemical substances) that it needs for business continuity in accordance with the laws/regulations in each country as well as the chemical substance management guidelines provided by customers.

In Japan, from conventional, Regarding the specific chemical substances that are necessary to continue our business activities, we carry out strict management on the use, storage, and disposal of these substances, based on the “Law Concerning Reporting, etc. of Releases to the Environment of Specific Chemical Substances and Promoting Improvements in Their Management.” In accordance with the PRTR system, when a designated chemical substance is released or transferred, we are aware of the amount and report it to the national government.

Whenever the EU regulations concerning Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), Global Automotive Declarable Substance List (GADSL), or customers’ lists of chemical substances management are revised, we adjust our operations accordingly.

Furthermore, we comply with the Ordinance on Prevention of Hazards Due to Specified Chemical Substances, the Ordinance on Prevention of Organic Solvent Poisoning, and related laws and ordinances based on the Industrial Safety and Health Act, and ensure that emission control measures using local exhaust ventilators, appointment of a work supervisor, measurement of the working environment, and medical checkups are conducted properly.

Main Materials used

(1000t)

| 2018 | 2019 | 2020 | ||

|---|---|---|---|---|

| Total weight of main materials | 332.8 | 314.0 | 252.3 | |

| Renewable | 190.7 | 187.6 | 148.1 | |

| Non-renewable | 142.1 | 126.4 | 104.3 | |

| Percentage of recycled input materials used to rubber material | 1.2% | 1.2% | 1.2% | |

Waste

Goal: Maintain a waste recycling rate of 100% (achieved by the end of December 2018)

Boundary:

TOYO TIRE Corp. (Headquarters, Sendai Plant, Kuwana Plant (tire/ Automotive Parts), Hyogo Manufacturing Complex, Tire Technical Center, Automotive Parts Technical Center, Corporate Technology Center, Tire Proving Ground), Fukushima Rubber Co., Ltd., Toyo Soflan Co., Ltd., Ayabe Toyo Rubber Co., Ltd., Orient Machinery Co., Ltd. (Headquarters, Sendai branch)

Management unit: Direct recycling amount*/ Total weight of waste×100

*Amount outsourced for recycling to a direct waste disposal company (Excludes direct landfill, in-house simple incineration, and outsourced simple incineration.)

FY2020 results: Waste recycling rate of 100%

Non-hazardous waste (industrial and general waste)

(1000t)

| 2018 | 2019 | 2020 | |

|---|---|---|---|

| Total weight of Non-hazardous waste | 32.5 | 31.0 | 25.7 |

| Recycled amount of non-hazardous waste | 16.1 | 12.2 | 9.6 |

| Reused amount of non-hazardous waste | 0.85 | 0.06 | 0.00 |

- * In 2019, our Sendai Plant converted its thermal energy source to natural gas, which resulted in a decrease in the amount of products reused within the company as a fuel.

(t)

| 2018 | 2019 | 2020 | |

|---|---|---|---|

| Total weight of Hazardous waste | 129.3 | 114.4 | 124.5 |

- *How the waste disposal method has been determined;

- Non-hazardous waste (industrial and general waste): Information provided by the waste disposal contractor

- Hazardous waste (special control industrial waste) *in Japan: Information provided by the waste disposal contractor

Transport of hazardous waste (PRTR-designated chemical substances)

| 2018 | 2019 | 2020 | |

|---|---|---|---|

| Handled | 3930.1 | 2977.5 | 2592.3 |

| Emitted | 179.2 | 164.7 | 117.1 |

| Transferred | 83.0 | 88.3 | 77.9 |

TOYO TIRES Brand, also known for High Quality Recycled (Retreaded) Tires

Collecting and recycling used tires is an important issue in the tire industry for recycling resources. As one solution, we are working to spread the use of retreaded tires.

Retreaded tires involve replacing the tread (the part of a tire that comes into contact with the road surface) on worn tires to make them serviceable again. Since retreading reuses all the remaining part of the tire, it naturally saves resources and even emits less CO2 than in manufacturing new tires*.

We produce and supply highly durable, high quality tires, and we have received high praise from users regarding retreaded products.

We contribute to the promotion of resource recycling in the transportation industry by spreading the use of high-quality retreaded tires.

- *Retreaded tires produce 41% less CO2 in comparison to new tires during production. (Source: Japan Retreader’s Association)

Total Production Shipments of Recycled (Retreaded) Tires *TOYO Brand

(1,000 units/year)

| 2018 | 2019 | 2020 | |

|---|---|---|---|

| Production output | 131.0 | 130.0 | 126.1 |

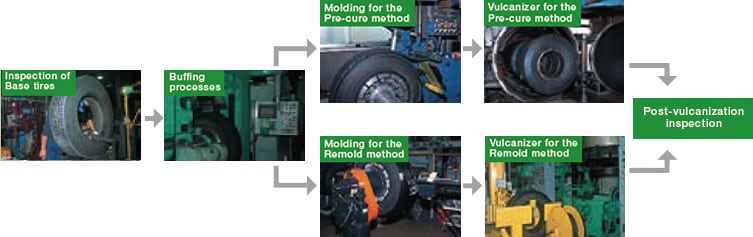

Retreaded tire production flow

There are two methods of retreading: In Remold method, new tread rubber is applied to tire casting. It is then placed in a mold and vulcanized to form tread. In Pre-cure method, previously prepared tread strip is applied to tire casing and vulcanized in a vulcanizer.

Our group has established high technology in both construction methods and produce with both.

Sustainability

- Message from the President

- TOYO TIRE Value creation

- TOYO TIRE Sustainability

-

TOYO TIRE Materiality

- Help create a society of sustainable mobility / Support the enjoyment of mobility for all

- Support diverse talent with motivating challenges and job satisfaction

- Continue innovating next-generation mobility technology

- Pursue decarbonization in all corporate activities

- Promote supply chain sustainability

- Ensure the fundamentals of manufacturing: quality and safety

-

ESG Activities

- E: Environment

- S: Upholding human rights

- S: Managing occupational health and safety to global standards

- S: Crisis management (responding resiliently to natural disasters, infections and other crises)

- S: Working with local communities (Helping solve local issues)

- G: Sound governance

- G: Compliance

- G: Risk management

- G: Information security

- G: Promoting digital transformation (borderless and centralized business management through ERP reform)

- External Recognition

- Report Library

- ESG Data

- ESG Data/Survey Index

- GRI Content Index

- Communication on Progress (CoP) Index

- Editorial Policy