Partnership with Business Partners

- Promotion of sustainable procurement

- Monitoring the Implementation of CSR Procurement Guidelines

- International collaboration on the sustainable procurement of natural rubber

Promotion of sustainable procurement

Creating a supply chain that supports sustainable procurement is indispensable for continuing to ensure a stable supply of raw materials with the quality and volume to support the growth of TOYO TIRE. Sustainable procurement means that we work toward resolving social issues throughout the entire supply chain, from production to consumption, and aims for sustainability in society.

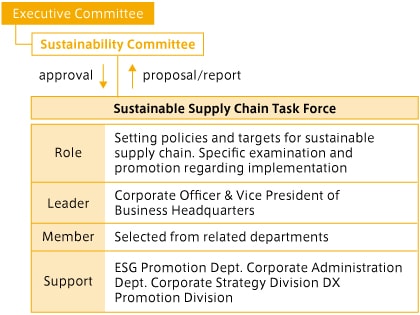

Because this is an urgent high priority issue for the Group, we have established Task force under the Sustainability Committee and discuss action plans, which include orientation, goals, and targets.

Monitoring the Implementation of CSR Procurement Guidelines

In line with the TOYO TIRE Group CSR Procurement Guidelines, we are working to resolve social issues throughout the entire supply chain from production to consumption, requesting our business partners to not only follow the Guidelines but also ask their own upstream suppliers to follow suit.

The Guidelines are updated as needed to reflect the demands of society and the changes in the business environment. As we expand the scope of global procurement, we have published the Guidelines in Japanese, English, and Chinese.

In 2020, we surveyed about 350 existing suppliers in Japan and overseas using the CSR Self-Inspection Checklist in order to have them report on their activities in accordance with our company’s CSR Procurement Guidelines. The results of responses from suppliers were reviewed for each guideline item, including compliance, products and services, human rights and labor, the environment, and responsible procurement, and for each supplier region. We will conduct due diligence based on the results of inspections.

Inviting WWF to Conduct a Workshop on "Sustainable Natural Rubber"

Toyo Tire Corporation believes it important to understand what is happening in natural rubber producing areas as we set about creating a sustainable natural rubber supply chain. Accordingly, in April 2021, we invited WWF Japan to give an online workshop on forest preservation and sustainable natural rubber.

Attended by members from our Purchasing, Engineering, Quality, Environment, and ESG departments, the workshop included technical lectures on biodiversity, protection of endangered wildlife, land development/use, and other topics, as well as forest preservation in areas where natural rubber is produced. The attendees not only deepened their understanding of these topics but also took this opportunity to see how the Sustainable Natural Rubber Procurement Policy relates to their operations and ponder the challenges that they may encounter when drawing up action plans.

Going forward, through communication and collaboration with such professional organizations/groups and stakeholders, we will forge ahead with initiatives for sustainable procurement.

International collaboration on the sustainable procurement of natural rubber

In the future, being able to procure a stable supply of natural rubber is a particularly important management issue for the Group, which uses natural rubber as the main raw material for manufacturing. Meanwhile, the natural rubber industry faces social issues, such as deforestation at production sites and infringement of the rights of local residents, and there is a worldwide movement to achieve sustainable procurement of natural rubber by resolving these issues.

Since 2016, we have endorsed the aims of the “Sustainable Natural Rubber Initiatives (SNR-i) *” proposed by the International Rubber Study Group (IRSG), and we have promoted CSR procurement while gaining the understanding of our business partners.

In addition, a new framework "Sustainable Nature" was launched in 2018 under the initiative of the Tire Industry Project (TIP) under the umbrella of the World Business Council for Sustainable Development (WBCSD). We are also participating in the Global Platform for Rubber (GPSNR) * 2 and are holding discussions to resolve issues.

In 2020, the GPSNR decided on the elements for policies that its participants need to develop to incorporate the GPSNR Sustainable Natural Rubber Principles into business activities. Accordingly, we made a full revision of our natural rubber procurement policy, which had been added to the CSR Procurement Guidelines in 2019, to draw up and announce the Sustainable Natural Rubber Procurement Policy. This brand new policy is aimed at increasing the effectiveness of our initiatives concerning ecological ecosystems, human rights, and communities.

We aim to build a sustainable natural rubber supply chain through our value chain in collaboration with international initiatives and stakeholders.

* Initiatives with the aim to support the improvement of productivity, enhancing quality, support forest sustainability, water management, and to demonstrate the highest respect for human and labor rights across the natural rubber supply chain.

** A platform that aims for production and use of natural rubber around the world to be conducted in a method that considers the natural environment and social issues, going beyond the norms of the industry.

Comment by Stefano Savi, Director, GPSNR

I am delighted to know that TOYO TIRE has announced its support for the GPSNR policy framework and institutionalized its commitment to a fair, equitable, and sustainable natural rubber value chain. With half of the stakeholders of natural rubber having a GPSNR membership, it is undoubtedly a positive step for the entire industry if TOYO TIRE and other member companies adopt the policy framework. I look forward to seeing how TOYO TIRE's initiatives in this regard will inspire other companies to support our policy framework.

Response to the Conflict Minerals Issues

Conflict minerals refer to tin, tantalum, tungsten, and gold mined in conflict areas.

Due diligence of the supply chain is required by law in Europe and the United States, as purchasing conflict minerals becomes a source of funds for local armed groups and promotes corruption such as human rights violations, bribery, and money laundering.

We conduct thorough investigations by tracing all the way back along the supply chain to smelter to determine whether the materials or products supplied to us contain conflict minerals from the relevant countries, in cooperation with our customers and suppliers.

Internal Reporting System

Our company has maintained a whistle-blowing system that can also be used by suppliers, and we inform our suppliers of this system through briefings on the CSR Procurement Guidelines. No complaints were reported through the system in 2020.

In addition, we have established dedicated hotline for reporting concerns and complaints in the natural rubber supply chain.

Action for Sustainability

- Message from the President

- TOYO TIRE Value creation

- TOYO TIRE Sustainability

- TOYO TIREʼs SDGs

-

TOYO TIRE Materiality

- Help create a society of sustainable mobility / Support the enjoyment of mobility for all

- Support diverse talent with motivating challenges and job satisfaction

- Continue innovating next-generation mobility technology

- Pursue decarbonization in all corporate activities

- Promote supply chain sustainability

- Ensure the fundamentals of manufacturing: quality and safety

-

Sustainability and ESG themes beyond the material issues

- E: Environment

- S: Upholding human rights

- S: Managing occupational health and safety to global standards

- S: Crisis management (responding resiliently to natural disasters, infections and other crises)

- S: Working with local communities (Helping solve local issues)

- G: Sound governance

- G: Compliance

- G: Risk management

- G: Information security

- G: Promoting digital transformation (borderless and centralized business management through ERP reform)

- Toyo Tire Group Charter of Corporate Behavior

- Toyo Tire Group Code of Conduct

- Site Report

- Report Library

- Editorial Policy

- GRI Content Index

- ESG Data/Survey Index

- Communication on Progress (CoP) Index

- External Recognition