Contribution to society through products and services

- Issues to be addressed

- Guiding Policies

- TOYO TIRE’s SDGs (Ideal Status in 2030)

- Goals

- Responsibilities (April 2021)

- Activity Promotion System (April 2021)

- Grievance Mechanism

- Main Resources (Fiscal 2020)

- Activities in 2020

Issues to be addressed

- Ensuring product quality based on thorough customer orientation

- Efforts to alleviate and adapt to climate change

- Development of human resources with technical expertise

In the business environment, TOYO TIRE foresees the following; further diversification of consumers, increased demand or tightening of regulations for products and services that concern climate change and globalization of the areas to which the Group’s products and services are distributed in the future, etc. We necessary to respond to these changes in the business environment. So, we regard our priority issues as the development and supply of products and services that meet the needs of the next-generation mobility society, strengthening of technological and material development to achieve this, improvement of quality, and training of human resources.

Affected Stakeholders

Directly: Customers, Business Partners (Car Manufacturers), Employees, Co-researchers & Joint Developers,

Indirectly: Shareholders and Investors, Creditors, Local Communities, NGOs, Business Organizations

Guiding Policies

"Striving for the highest level of quality, safety, and societal benefits in our products and services"—True to this guiding principle as a manufacturer, we clearly state our fundamental philosophy and action guidelines regarding product safety in the "Toyo Tire Group Global Product Safety Policy."

On the R&D front, we are developing products and services that have minimal impact on the environment. To assure product quality and safety, we operate a quality management system based on ISO 9001 and IATF 16949 (formerly ISO/TS 16949) to manage risks.

Global Product Safety Policy

1. Fundamental Philosophy

As a responsible global company, we will promote sustainable management through our corporate activities to further enhance economic, environmental and social value.

We continue to strive and contribute to the creation of sustainable society as global environment protection first, which is put not only safe but also human health harmless.

2. Action Guidelines

- -1. As a company aiming for sustainable growth by creating a better symbiotic relationship between people and the earth, we provide environmentally friendly, safe and reliable products and services to our customers and society.

- -2. To assure the safety of products, we comply with the necessary internal and external rules, laws, regulations, standards and guidelines. We aim to develop products with a higher level of safety and lower environmental impact.

- -3. We consider product safety and global environment protection from the stages of product planning, development and design, through to production, sales, use, and even after the end of use.

- -4. We aim to manufacture without the production loss from the product planning, development, and design stages.

- -5. We consider recycling in the product planning, development, and design stages.

- -6. We conduct education and awareness-raising concerning every employee layer regarding product safety and environmental protection.

- -7. We well-inform and educate customers about methods of suitable use for products and misuse prevention. And we listen earnestly to their opinions and desires, and reflect them in our products. Thus, we will provide the safe and health-friendly products, and promote the global environmental protection.

Quality Management System Certification Status

- ■ISO9001 (Certified by the end of January 2021)

Production facilities: 16 sites

- - Toyo Tire Corporation: 3 sites*

- - Affiliated companies: 13 sites

- *The Kuwana Plant has independently acquired certification at both its tire production plant and automobile parts plant (2 business sites).

- ■IATF16949* (Certified by the end of January 2021)

*the former ISO/TS16949

Production facilities: 9 sites

- - Toyo Tire Corporation: 2 sites

- - Affiliated company: 7 sites

TOYO TIRE’s SDGs (Ideal Status in 2030)

We will contribute;

- - to widespread of mobilities that will be enable social participation by using higher functionality technologies.

- - to progress of mobilities by focusing on adding of value of products and technologies.

- - to the mobility industry efforts that will adapt to climate change and aim to mitigate the influence by climate change by innovations.

- - to sustainable resource recycling through optimization of resource utilization and improvement of product durability.

- - to realize the safe and secure mobility society through implementing safety awareness and supporting for improving maintenance skills.

Goals

As a quality improvement Goal, through the product planning and production transfer preparation stages, which include logistics from material purchases through delivery of products to customers, we perform quality risk analysis (quality planning and quality design) for each process and are sure to reflect that in each R&D project.

We will work to ascertain the state of their quality with a constant awareness of customer satisfaction by referring customer opinions of our products and services. Through the collaboration between the Quality Assurance, Production, Sales, Engineering, and other departments, we will work to make improvements in order to provide even higher quality products. We also push forward with efforts to improve current issues from various perspectives through personnel exchanges with all Group companies.

We will improve functionality (environmentally friendly and safety) in all product development activities, which are our goals in solving environmental and social issues through our products and services. We will also promote human resource training and personnel exchanges (research and technology), which support these technological innovations.

Responsibilities (April 2021)

R&D:Corporate Officer & Vice President of R&D Headquarters

Production Engineering:Corporate Officer & Vice President of Production Headquarters

Provision of products and services:Corporate Officer & Vice President of Sales Headquarters

Quality Assurance:Corporate Officer & Vice President of Quality Assurance, Environment & Safety Headquarters

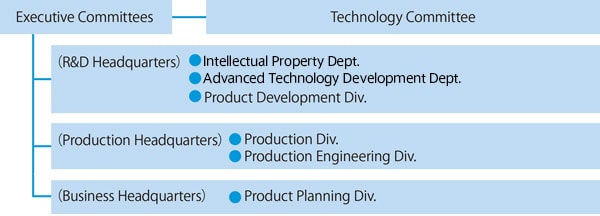

Activity Promotion System (April 2021)

R&D

Quality Assurance

TOYO TIRE belongs to the following trade associations:

Grievance Mechanism

- Reporting Hotline (Creating an Internal Control System) *Targets: Employees, Business Partners

- Customer Relations Department *Targets: Customers, Local Communities

- Inquiry Form (on the Website) *Targets: Customers, Shareholders and Investors, NGOs

In addition to responses that use the above as a point of contact, our Technical Service Department and the Group’s sales companies and distributors handle consultations and complaints related to products and services

Main Resources (Fiscal 2020)

- R&D expenditures: 10,437 billion yen *Of which, 1,145 billion yen is for basic research.

- Expenses related to environmental protection during R&D: 315 million yen

- Capital investments to streamline operations, improve quality, and reinforce production equipment: 26,967 billion yen

- Technological research bases: 8 sites (Japan, U.S., Malaysia and Germany)

TOYO TIRE intends to construct a new tire plant in the Republic of Serbia. Prior to this, in the fall of 2019, we established Europe R&D Center in Germany in an attempt to build a solid technological foundation, reinforce product development, and establish proprietary technologies with a focus on next-generation mobility in Europe.

Furthermore, we conduct joint research with numerous universities and research institutions in order to solve environmental and social issues.

Activities in 2020

Sustainability

- Message from the President

- TOYO TIRE Value creation

- TOYO TIRE Sustainability

-

TOYO TIRE Materiality

- Help create a society of sustainable mobility / Support the enjoyment of mobility for all

- Support diverse talent with motivating challenges and job satisfaction

- Continue innovating next-generation mobility technology

- Pursue decarbonization in all corporate activities

- Promote supply chain sustainability

- Ensure the fundamentals of manufacturing: quality and safety

-

ESG Activities

- E: Environment

- S: Upholding human rights

- S: Managing occupational health and safety to global standards

- S: Crisis management (responding resiliently to natural disasters, infections and other crises)

- S: Working with local communities (Helping solve local issues)

- G: Sound governance

- G: Compliance

- G: Risk management

- G: Information security

- G: Promoting digital transformation (borderless and centralized business management through ERP reform)

- External Recognition

- Report Library

- ESG Data

- ESG Data/Survey Index

- GRI Content Index

- Communication on Progress (CoP) Index

- Editorial Policy